Single point load cells are one of the most widely used and versatile types of load cells in modern industrial and commercial weighing applications. These compact and highly precise sensors are engineered to measure force or weight in a single location, making them ideal for smaller platforms and devices where uniform weight distribution is critical. Despite their small size, they offer outstanding performance, durability, and accuracy, thanks in part to their integration with advanced sensing technologies like strain gauges.

What Are Load Cells

To fully appreciate the function and benefits of single point load cells, it’s important to first understand what a load cell is and how it works. A load cell is a transducer that converts a mechanical force into an electrical signal. These devices are foundational in various sectors, including manufacturing, automotive, aerospace, and healthcare, enabling precise measurement and control of mechanical forces. The core operating principle behind most load cells is strain measurement, often facilitated by foil strain gauges, which are bonded to a structural element that deforms under load.

What is a Single Point Load Cell?

A single point load cell is a specific type of load cell designed to measure force at a single location while maintaining measurement integrity across the entire platform it supports. This means that the load cell can accurately weigh an object even if it’s placed off-center on the weighing platform. This property, known as “off-center load compensation,” is what makes single point load cells indispensable in small-scale applications such as retail scales, packaging machines, and medical devices.

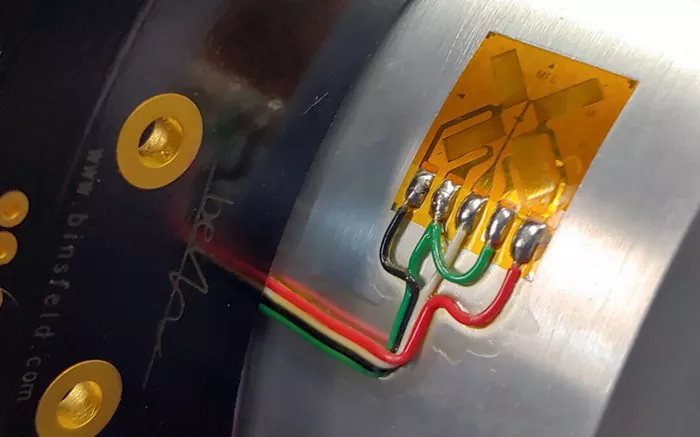

The design of a single point load cell typically features a strain gauge configuration mounted on an aluminum or stainless-steel beam. When force is applied to the platform, the beam flexes slightly, and the strain gauges detect this deformation. The deformation, or strain, is then converted into an electrical signal, which can be interpreted by digital instruments or controllers.

How Do Single Point Load Cells Work?

The working principle of a single point load cell revolves around the mechanical deformation of a strain body and the electrical output it generates. Here’s a step-by-step breakdown of how this process occurs:

- Load Application: When weight is applied to the platform connected to the load cell, it exerts a mechanical force on the load cell’s structure.

- Strain Induction: This force causes the internal metal structure to deform slightly. Strain gauges attached to this structure detect the amount of strain (deformation).

- Signal Conversion: The strain gauges, typically arranged in a Wheatstone bridge circuit, convert the mechanical strain into a small electrical voltage.

- Signal Amplification and Processing: This voltage signal is then amplified and transmitted to a signal processor or digital indicator, which displays the weight or force being applied.

Because the load cell can handle forces applied at various points across the platform, it provides consistent readings even when loads are unevenly distributed — a key advantage over other types of load cells that require centered loading.

Core Components and Design Considerations

A typical single point load cell consists of several critical components, each playing a vital role in the functionality and reliability of the sensor:

- Elastic Element: Usually made from high-strength aluminum or stainless steel, this is the part of the cell that physically deforms under load.

- Strain Gauges: Bonded to the elastic element, these gauges measure the strain induced by the applied force. Foil strain gauges are most commonly used due to their durability and precision.

- Wheatstone Bridge Circuit: This configuration enhances the accuracy of the strain measurement and helps cancel out temperature-induced signal fluctuations.

- Protection and Sealing: Load cells often include environmental sealing to protect the sensitive gauges from moisture, dust, and other contaminants.

Applications of Single Point Load Cells

The simplicity, precision, and robustness of single point load cells make them suitable for a wide variety of applications. Common usage scenarios include:

- Retail Weighing Scales: Often used in supermarkets and grocery stores, single point load cells are integrated into digital price-computing scales for accurate weight measurements.

- Medical Equipment: Devices such as patient beds, infusion pumps, and wheelchair scales rely on these load cells for precision and reliability.

- Packaging Machinery: Automatic packaging systems use single point load cells to ensure accurate product weights for compliance and quality control.

- Industrial Automation: These load cells are embedded in assembly lines and quality assurance systems to monitor and control force-sensitive processes.

Advantages of Single Point Load Cells

There are several reasons why single point load cells are preferred in many applications:

- Off-center Loading Compensation: Ensures consistent readings regardless of where the load is placed on the platform.

- Compact and Lightweight: Ideal for limited-space applications.

- Cost-Effective: Affordable manufacturing and integration costs make them suitable for high-volume production environments.

- High Precision: Excellent repeatability and low hysteresis contribute to accurate weight measurements.

- Durability: Designed to withstand overloads and harsh environments with protective housings and corrosion-resistant materials.

Challenges and Limitations

Despite their many advantages, single point load cells do have some limitations:

- Limited Load Capacity: They are typically used for lower capacity applications (generally up to a few hundred kilograms).

- Sensitivity to Mechanical Misalignment: Installation errors or improper mounting can affect accuracy.

- Temperature Sensitivity: While modern models include temperature compensation, extreme environments can still impact performance.

Material Selection and Manufacturing Process

The material used in a single point load cell significantly impacts its performance. Aluminum is common for low-capacity cells due to its light weight and ease of machining, while stainless steel is preferred for high-capacity or harsh-environment applications. Manufacturing involves precision machining of the metal body, careful placement and bonding of strain gauges, and rigorous calibration to ensure accuracy.

Advanced welding or adhesive techniques are used to seal the load cell, protecting internal components from dust, moisture, and chemicals. In high-end models, hermetic sealing ensures even better protection, enabling their use in cleanrooms or washdown environments.

Calibration and Testing

Every single point load cell undergoes a series of calibrations to ensure compliance with international standards such as OIML or NIST. Calibration involves applying known weights and measuring the electrical output to create a precise correlation between load and signal.

Testing procedures may include:

- Linearity Tests: Confirm that the output is proportional across the full range of applied weights.

- Repeatability Tests: Ensure the cell delivers consistent results over multiple load applications.

- Creep and Hysteresis Checks: Evaluate long-term performance and lag in signal return when loads are applied and removed.

Trends in Single Point Load Cell Technology

As industries demand higher performance from their measurement systems, single point load cell technology continues to evolve. Recent innovations include:

- Digital Load Cells: Equipped with onboard signal processing for enhanced noise immunity and real-time data output.

- Miniaturization: Compact designs that enable integration into wearables, prosthetics, and other space-constrained applications.

- Wireless Communication: Load cells now support Bluetooth and Wi-Fi for remote monitoring and data logging.

- Smart Algorithms: Advanced software enables automatic calibration, error detection, and predictive maintenance.

Conclusion

Single point load cells represent a critical component in modern force measurement systems, providing accurate, repeatable, and robust performance in a wide variety of settings. Their ability to maintain precision under off-center loading conditions makes them indispensable in applications ranging from retail to robotics. By integrating technologies such as load cells with advanced electronics and data systems, the future points toward even more reliable, efficient, and intelligent sensing solutions.

Whether in an automated factory floor or a hospital patient bed, the unassuming single point load cell quietly performs the essential task of ensuring measurements are trustworthy and consistent — a testament to the power of engineering innovation.