Laser sensors are devices that utilize laser beams to detect or measure a variety of physical characteristics such as distance, speed, and even the presence of objects. They are a vital tool in a wide range of industries including manufacturing, automotive, aerospace, and robotics. By leveraging the precision and accuracy of laser technology, these sensors offer unparalleled performance when compared to other sensing technologies. This article delves into the fundamentals of laser sensors, their operating principles, and their various applications.

What Are Laser Sensors

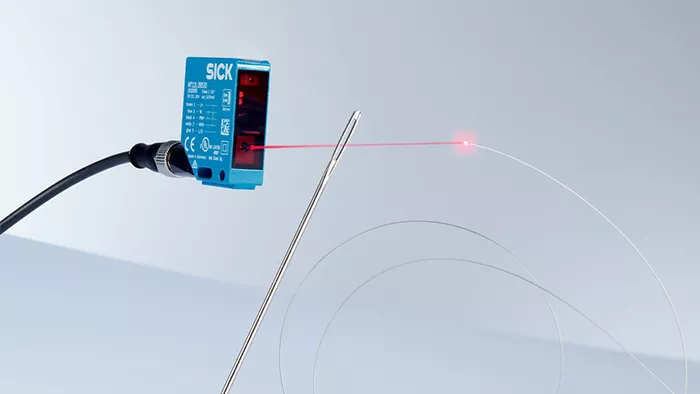

Laser sensors operate by emitting a laser beam, which interacts with a target object and then returns to the sensor. The time it takes for the laser to return (known as the time-of-flight) or the shift in frequency or amplitude of the returned beam can be used to extract useful data, such as distance, speed, or surface characteristics. There are several types of laser sensors, each suited to specific applications and environments. These sensors are known for their precision, versatility, and high-speed performance.

Types of Laser Sensors

Laser sensors can be categorized into several types based on their functionality, such as:

Time-of-Flight (ToF) Sensors

Time-of-flight sensors measure the time it takes for a laser pulse to travel to the target and return to the sensor. This type of laser sensor is particularly useful in applications where high precision and long-range measurements are required. ToF sensors are commonly used for distance measurement and 3D scanning applications.

Laser Displacement Sensors

Laser displacement sensors, also known as laser triangulation sensors, determine the position or displacement of an object by using the triangulation method. A laser beam is directed at the target, and the reflected light is captured by a sensor. The angle of reflection is then used to calculate the displacement. These sensors are widely used for measuring the thickness of materials, surface profiling, and detecting small displacements with high accuracy.

Laser Doppler Sensors

Laser Doppler sensors use the Doppler effect to measure the velocity or speed of an object. As the object moves, the frequency of the laser light is shifted. This shift is directly proportional to the speed of the object. Laser Doppler sensors are commonly used in applications requiring precise measurement of moving objects, such as in wind tunnel testing or vibration analysis.

How Laser Sensors Work

Laser sensors work by emitting a laser beam, typically from a diode or fiber optic source. The beam interacts with the target object and then returns to the sensor. Depending on the sensor type, the way the laser interacts with the target can differ.

Distance Measurement

In the case of time-of-flight sensors, the laser pulse is emitted and reflected by the object. The sensor measures the time interval between the emission and reception of the light, calculating the distance based on the speed of light. This method allows for precise measurement of distances over long ranges, often up to several kilometers.

Triangulation

Laser triangulation sensors use the geometry of the reflected light to calculate the distance to the target. The laser beam is directed at the target, and the reflected light is captured at a specific angle. By measuring the angle at which the light is reflected, the sensor can calculate the distance from the sensor to the object. This method is ideal for measuring small distances with high accuracy and is often used in industrial applications.

Doppler Effect

In laser Doppler sensors, the laser beam is reflected off a moving object. As the object moves, the frequency of the reflected light changes due to the Doppler effect. This change in frequency is proportional to the speed of the object, allowing the sensor to calculate its velocity. This method is frequently used in fluid flow measurements, such as in flow sensors and applications involving motion analysis.

Applications of Laser Sensors

Laser sensors are used in a wide range of industries due to their versatility, precision, and reliability. Some common applications include:

Distance and Position Measurement

Laser sensors are widely used in applications that require precise distance measurements. For example, in automated manufacturing systems, laser sensors can measure the distance between components to ensure proper alignment. In robotics, laser sensors enable precise positioning of robotic arms and tools.

Speed and Velocity Measurement

Laser Doppler sensors are commonly used to measure the speed of moving objects. These sensors are frequently employed in traffic monitoring systems to measure the speed of vehicles, as well as in research applications such as aerodynamic testing. Their ability to measure speed without physical contact makes them ideal for high-speed measurements in harsh environments.

Surface Profiling

Laser displacement sensors are often used for surface profiling applications. For example, they can measure the surface roughness of materials such as metal, plastic, and glass. These sensors provide highly accurate measurements that help ensure the quality of products in manufacturing environments. They are also used in research and development to study surface characteristics in detail.

Quality Control and Inspection

Laser sensors are essential in quality control processes, particularly in industries like automotive, aerospace, and electronics. They can be used for measuring the thickness of materials, detecting surface defects, and verifying the precision of manufactured parts. Laser sensors provide rapid, non-contact measurements, which are crucial in maintaining high-quality production standards.

3D Scanning and Mapping

In the field of 3D scanning, laser sensors are used to create detailed models of objects and environments. These sensors can scan large areas with high precision, capturing depth information and enabling the creation of 3D representations of physical objects. This technology is used in various fields, including architecture, archaeology, and virtual reality.

Benefits of Using Laser Sensors

Laser sensors offer several advantages over other types of sensors, making them ideal for many applications. Some of the key benefits include:

High Precision and Accuracy

Laser sensors are known for their exceptional precision and accuracy. Unlike other types of sensors, which may be affected by environmental factors like temperature or humidity, laser sensors are not influenced by these variables to the same extent. This makes them particularly useful in environments where high precision is essential.

Non-Contact Measurement

One of the most significant advantages of laser sensors is their ability to take measurements without physical contact with the target object. This feature makes them ideal for measuring delicate, fragile, or hazardous objects that cannot be touched directly. Non-contact measurement also reduces the risk of wear and tear on both the sensor and the target object.

High Speed and Real-Time Data

Laser sensors can provide real-time data, which is crucial in many applications. For instance, in industrial automation, laser sensors can continuously monitor the position and movement of components on a production line, allowing for immediate adjustments and optimizing production processes.

Versatility in Harsh Environments

Laser sensors can operate in a variety of environments, including those with high temperatures, vibrations, and other challenging conditions. Their ability to function in harsh environments makes them suitable for use in industries such as aerospace, automotive, and heavy manufacturing.

Conclusion

Laser sensors are incredibly versatile and precise tools that are used in a wide range of industries for various applications, from distance measurement to surface profiling and speed analysis. The ability to operate non-contact, combined with their high accuracy, makes them an invaluable tool in modern engineering and manufacturing. Whether you are measuring the speed of a moving vehicle, inspecting the quality of a product, or scanning a 3D environment, laser sensors offer the precision and reliability needed for success. As technology continues to evolve, it is likely that laser sensors will play an even more significant role in the development of innovative solutions across multiple fields.