Water flow meters are vital instruments used across various industries and applications to measure the flow rate of water through pipelines or channels. Their accurate monitoring and control capabilities are essential for water management, process optimization, and ensuring operational efficiency. From municipal water supply systems to industrial cooling circuits, water flow meters provide critical data that supports decision-making, reduces wastage, and enhances system reliability.

This article explores the top 10 advantages of using a water flow meter, highlighting how these devices improve system performance, promote sustainability, and reduce costs. By integrating key technological advancements, such as instrumentation innovations, water flow meters have evolved to become indispensable tools in fluid measurement.

1. Accurate Measurement of Flow Rate

The primary advantage of a water flow meter is its ability to deliver precise and reliable measurements of water flow rates. This accuracy is crucial for maintaining the desired water supply levels in various systems, ensuring that processes relying on water receive the correct volume. Many modern water flow meters utilize advanced technologies such as electromagnetic or ultrasonic measurement methods, which minimize errors caused by flow disturbances or changes in fluid properties.

2. Improved Water Resource Management

Efficient water management has become a global priority amid growing water scarcity. Water flow meters allow operators to monitor consumption in real-time, identify leaks, and detect unauthorized usage, thus promoting responsible water use. By analyzing flow data, municipalities and industries can implement water-saving strategies and optimize distribution networks, ultimately reducing environmental impact.

3. Cost Reduction Through Leak Detection

Leaks in water supply systems can lead to significant economic losses and resource wastage. Water flow meters help detect irregular flow patterns that indicate leaks, enabling timely repairs. This proactive approach saves costs associated with lost water, potential damage to infrastructure, and the need for emergency interventions. In this respect, integrating flow meters into water distribution networks is a sound investment.

4. Enhanced Pr2ocess Control and Automation

In industrial settings, water flow meters provide real-time data essential for process control and automation. By feeding accurate flow information to control systems, operators can maintain optimal operating conditions, regulate cooling systems, and ensure consistent product quality. This integration reduces manual intervention, improves safety, and enhances overall process efficiency.

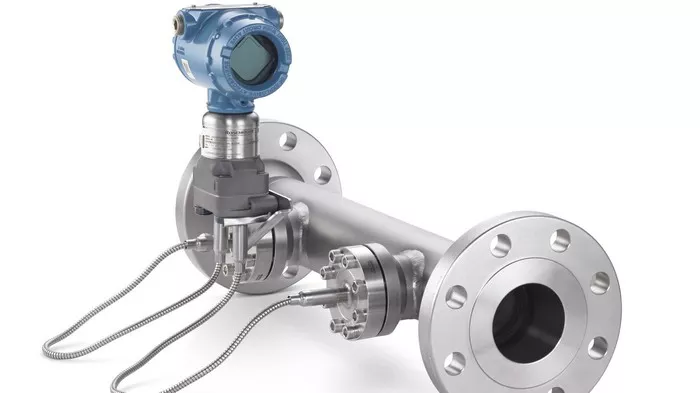

5. Compatibility with Various Measurement Technologies

Water flow meters come in multiple designs and operate on different principles, such as turbine, electromagnetic, or Coriolis flow meters. This diversity allows users to select devices tailored to specific application requirements, including flow range, fluid composition, and installation environment. For instance, a Coriolis flow meter offers highly accurate mass flow measurement, making it suitable for complex industrial processes.

6. Low Maintenance and Long Service Life

Modern water flow meters are designed to be durable and require minimal maintenance. Many models have no moving parts, which reduces wear and tear and extends their operational lifespan. This reliability translates to fewer service interruptions and lower maintenance costs over time, enhancing the return on investment for system operators.

7. Wide Range of Application Scenarios

Water flow meters are versatile and used in a variety of sectors, including municipal water treatment, irrigation, HVAC systems, and chemical processing. Their adaptability to different pipe sizes, pressure ranges, and water qualities makes them suitable for both small-scale and large-scale operations. This flexibility ensures that virtually any water measurement challenge can be addressed effectively.

8. Real-Time Monitoring and Data Logging

With advancements in digital technology, many water flow meters now feature real-time monitoring capabilities and data logging functions. Operators can track flow rates remotely, analyze historical trends, and generate reports to support regulatory compliance or system optimization. These features empower organizations to make data-driven decisions that enhance operational performance.

9. Environmentally Friendly Operation

By facilitating accurate water usage monitoring and leak detection, water flow meters contribute to environmental conservation efforts. Reduced water wastage and optimized consumption decrease the strain on natural water sources and energy used for water treatment and distribution. Additionally, some flow meters are designed with eco-friendly materials and low energy consumption in mind, further supporting sustainability goals.

10. Easy Installation and Integration

Many water flow meters are designed for straightforward installation, requiring minimal pipeline modification or downtime. Their compatibility with standard control systems and communication protocols, such as Modbus or HART, simplifies integration into existing infrastructure. This ease of deployment reduces installation costs and accelerates project timelines.

Conclusion

Water flow meters are indispensable devices that bring a host of benefits to water management and industrial applications. Their precision, reliability, and adaptability make them essential for optimizing resource use, reducing operational costs, and supporting sustainable practices. Whether for municipal water supply, industrial process control, or irrigation, investing in the right water flow meter technology ensures long-term value and operational excellence.

FAQs

Q1: What types of water flow meters are most commonly used?

Common types include turbine flow meters, electromagnetic flow meters, ultrasonic flow meters, and Coriolis flow meters. Each type has specific advantages depending on the application, fluid type, and accuracy requirements.

Q2: How do I select the right water flow meter for my application?

Consider factors such as the flow rate range, pipe size, fluid properties, required accuracy, installation environment, and budget. Consulting with instrumentation experts can help identify the most suitable meter.

Q3: Can water flow meters detect leaks in a pipeline?

Yes, by monitoring flow rate patterns and identifying anomalies, water flow meters can help detect leaks early, preventing water loss and damage.

Q4: Are water flow meters compatible with modern automation systems?

Most modern water flow meters support integration with automation and control systems via standard communication protocols, facilitating real-time data exchange and remote monitoring.

Q5: What maintenance is required for a water flow meter?

Maintenance depends on the meter type. Generally, meters without moving parts require minimal upkeep, while mechanical meters might need periodic inspection and cleaning to ensure accuracy.