Oxygen flow meters are critical instruments widely used in medical, industrial, and laboratory settings to regulate and measure the precise flow of oxygen gas. Ensuring the accurate performance of an oxygen flow meter is vital for patient safety, process control, and operational efficiency. Testing these devices involves systematic procedures to verify their functionality, accuracy, and reliability over time.

This article presents a comprehensive, step-by-step guide on how to test an oxygen flow meter, integrating fundamental principles of instrumentation and practical engineering approaches. We will explore the necessary equipment, preparation, testing methods, troubleshooting techniques, and safety considerations. Additionally, the guide incorporates insights about different types of flow meters, including the use of turbine flow meters in oxygen measurement.

Understanding the Basics of Oxygen Flow Meters

An oxygen flow meter is designed to measure the volumetric flow rate of oxygen gas passing through a system. Most commonly, these devices use mechanical principles such as float displacement (rotameters), or turbine flow mechanisms, to gauge flow rates. The accuracy of these meters is crucial, especially in medical applications where oxygen delivery must be precisely controlled.

Oxygen flow meters generally consist of a flow tube, a float or rotor, scale markings, and sometimes electronic sensors. Calibration and testing ensure the device’s readings correspond accurately to the actual oxygen flow. Improper functioning can lead to under- or over-delivery of oxygen, potentially causing serious harm.

Pre-Test Preparation

Before beginning any test on an oxygen flow meter, it is essential to prepare carefully to avoid errors and ensure safety:

1. Gather Necessary Equipment

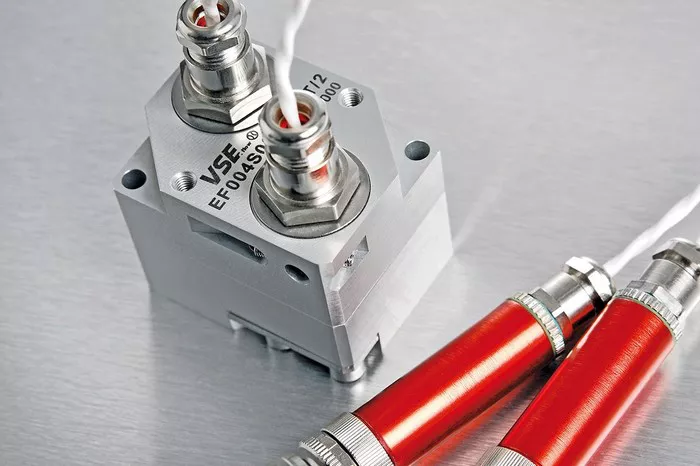

- Calibrated reference flow meter (e.g., turbine flow meter or mass flow meter)

- Oxygen supply source with pressure regulation

- Pressure gauges and temperature sensors

- Data logging tools or flow rate measurement instruments

- Safety equipment such as gloves and goggles

- Cleaning supplies to remove contaminants from the meter

2. Inspect the Oxygen Flow Meter

Perform a thorough visual inspection to detect any physical damage, contamination, or obstruction inside the meter. Check for cracks, leaks, or worn seals that could affect performance.

3. Verify Calibration Certificates

Ensure that the reference flow meters and instrumentation used for testing are recently calibrated and traceable to national standards.

4. Safety Considerations

Because oxygen is highly reactive and can pose fire hazards, make sure to work in a well-ventilated area, free from sources of ignition, and handle cylinders with caution.

Step-by-Step Procedure to Test an Oxygen Flow Meter

Step 1: Connect the Oxygen Flow Meter to the Test Setup

Install the oxygen flow meter in a controlled test rig where oxygen flow can be regulated and measured accurately. The test rig should include:

- An oxygen supply regulated to the desired test pressure

- A reference flow meter installed in series downstream or upstream of the meter under test

- Pressure and temperature sensors to monitor conditions during testing

Step 2: Perform Leak and Integrity Tests

Before flow testing, pressurize the system with oxygen at a low flow rate and check for leaks using soapy water or leak detection equipment. Confirm that all seals and fittings are intact to prevent gas escape and ensure test accuracy.

Step 3: Stabilize Flow Conditions

Gradually increase the oxygen flow to the desired starting point, allowing the system to stabilize. Avoid sudden surges that could cause erratic readings or damage the meter components.

Step 4: Record Baseline Readings

Note the flow meter reading at zero or near-zero flow to establish a baseline. Confirm that the meter’s needle or digital display returns to zero when no flow is present.

Step 5: Incrementally Increase Flow Rate and Record Readings

Increase the flow rate stepwise across the meter’s operating range. At each flow step:

- Allow the flow to stabilize

- Record the reading from the oxygen flow meter

- Record the reference flow meter reading simultaneously

- Note environmental conditions such as temperature and pressure

Typical steps might range from 0.1 L/min to the maximum rated flow, depending on the meter specifications.

Step 6: Analyze Accuracy and Repeatability

Compare the oxygen flow meter readings against the reference meter at each step. Calculate the percentage error and assess whether it lies within the manufacturer’s tolerance limits. To evaluate repeatability, repeat the flow steps multiple times and observe the variance in readings.

Step 7: Perform Functional Checks for Mechanical Components

If applicable, manually move the float or rotor inside the flow meter to check for smooth movement and absence of sticking. Mechanical flow meters such as turbine flow meters should spin freely and consistently without obstruction.

Step 8: Document Test Results and Calibration Adjustments

Record all test data, errors, and observations in a calibration or maintenance report. If discrepancies are beyond allowable limits, proceed with recalibration or repair as needed.

Troubleshooting Common Issues

1. Inconsistent Readings

Causes include turbulence upstream, partial obstruction, or sensor malfunction. Ensure adequate straight pipe length before the meter and clean the meter internals.

2. Stuck Float or Rotor

Contamination or mechanical wear may cause the float to stick, resulting in erroneous readings. Cleaning or replacing worn parts is recommended.

3. Calibration Drift

Over time, calibration can drift due to environmental factors or component aging. Regular recalibration with traceable standards helps maintain accuracy.

Additional Considerations for Oxygen Flow Meter Testing

Environmental Factors

Temperature and pressure fluctuations affect gas density and flow measurement. Compensation for these variables is necessary for precise readings.

Meter Selection and Technology

Choosing the right type of flow meter is essential for specific applications. For example, turbine flow meters offer high accuracy for oxygen flow measurement with minimal pressure drop, while rotameters provide a simple, visual indication of flow.

Compliance and Standards

Testing and calibration should comply with relevant industry standards such as ISO, ANSI, or ASTM to ensure quality and reliability.

Conclusion

Testing an oxygen flow meter is a critical process that ensures safety, reliability, and accuracy in oxygen delivery systems. By following a structured step-by-step approach—including proper preparation, systematic measurement, and thorough analysis—engineers and technicians can maintain optimal performance and detect issues before they escalate. Incorporating trusted instrumentation methods and understanding the underlying flow meter technology will enable effective testing and long-term operational confidence.

FAQs

Q1: How often should an oxygen flow meter be tested?

Testing frequency depends on usage and regulatory requirements, but typically, flow meters should be tested and calibrated at least annually or whenever there is suspicion of inaccurate readings.

Q2: Can I test an oxygen flow meter without a reference flow meter?

While possible, testing without a calibrated reference meter is not recommended as it compromises the accuracy of the test. A reliable reference meter is essential for comparison.

Q3: What are the risks of using a faulty oxygen flow meter?

A faulty meter can lead to incorrect oxygen delivery, potentially causing patient harm or compromising industrial processes.

Q4: What is the difference between a rotameter and a turbine flow meter for oxygen measurement?

A rotameter is a mechanical device that uses a float in a tapered tube to indicate flow visually, whereas a turbine flow meter measures flow by the rotational speed of a turbine placed in the flow stream, offering greater accuracy and electronic output options.

Q5: How do environmental conditions affect oxygen flow meter readings?

Changes in temperature and pressure affect gas density, influencing flow measurement. Proper compensation or correction factors must be applied to maintain accuracy.