Inflators are essential mechanical devices used to fill objects like tires, sports equipment, and even life jackets with air or gas, increasing the internal pressure of the object. These devices find wide applications in everyday life, industries, and specialized fields such as automotive, sports, and safety equipment. In this article, we will explore the types of inflators, the mechanics behind their operation, their uses, and the various technologies incorporated into modern inflators. The goal is to provide a comprehensive understanding of this vital yet often overlooked piece of equipment.

What Are Inflators

Inflators are devices designed to inject air or gas into an object to increase its internal pressure. The need for inflation arises in various contexts, from maintaining tire pressure for vehicles to ensuring the proper pressure in sports balls, or inflating life jackets to provide buoyancy. The principle behind an inflator is relatively simple, yet its application is crucial for maintaining the functionality and safety of the objects they inflate.

Inflation devices come in many forms, from small handheld pumps to large industrial machines that can inflate large tires or vessels. The most common example that most people encounter is the tire inflator at gas stations, where drivers inflate their vehicle tires to the recommended air pressure.

Types of Inflators

Inflators can be classified into several types based on their working mechanisms, size, and the kind of objects they are designed to inflate. The major types include:

Manual Inflators

Manual inflators require physical effort to generate the pressure needed to fill an object with air. These devices usually consist of a hand pump or foot pump, both of which rely on human power to force air into the object.

Hand Pumps: These are commonly used for inflating items like basketballs, bicycles, and small air mattresses. They typically consist of a cylinder and piston mechanism. When the piston is pushed in, air is compressed and forced through a nozzle into the object.

Foot Pumps: Foot-operated pumps, or pedal pumps, are used to inflate items like bicycle tires and sports equipment. The user steps on a pedal to create the air pressure needed to fill the object.

Electric Inflators

Electric inflators are powered by electricity and are designed for more effortless inflation of larger objects. They often feature motors that drive a pump mechanism to move air at higher pressure rates than manual pumps. These inflators are used for inflating car tires, air mattresses, inflatable boats, and other large equipment.

Tire Inflators: These inflators are commonly found in gas stations and garages. They operate by drawing air from the atmosphere and compressing it to the desired pressure. The inflator then pumps this compressed air into the tire until it reaches the optimal PSI (pounds per square inch).

Portable Electric Inflators: These devices are designed for personal use, often being compact and portable, ideal for inflating car tires, rafts, and inflatable pools. They may feature digital pressure gauges and automatic shut-off functions to prevent over-inflation.

CO2 Inflators

CO2 inflators are small, portable devices that use compressed carbon dioxide (CO2) cartridges to quickly inflate tires, sporting equipment, and other objects. These inflators are commonly used for bicycle tires and in emergency situations, as CO2 is stored in pressurized canisters and can rapidly inflate an object in seconds.

CO2 inflators are small and lightweight, making them ideal for cyclists and other people who need a compact solution for inflation. They are usually less durable than electric inflators but are invaluable in situations where speed is critical.

Industrial Inflators

Industrial inflators are larger, more powerful machines designed to inflate large equipment such as vehicle tires, air bags, or large inflatable structures. These inflators can be powered by electricity, diesel engines, or compressed air and are commonly used in tire manufacturing, construction, and various industrial processes.

Industrial inflators are capable of achieving much higher air pressures and flow rates, allowing them to fill tires of heavy machinery, aircraft, or large transport vehicles.

How Does an Inflator Work?

The working principle behind inflators is based on the laws of fluid dynamics and pressure. Air (or another gas) is drawn into the inflator and forced into the object being inflated through a valve or nozzle. The key to understanding how an inflator works lies in the concept of compression, as air is compressed into the object, increasing its internal pressure.

Air Compression Process

At the heart of an inflator is a compressor, which is responsible for compressing the air to a higher pressure than the surrounding atmosphere. The basic steps involved in this process are as follows:

Air Intake: The inflator draws in ambient air from the surrounding environment through an intake valve.

Compression: The air is then compressed using a mechanical pump (or, in some cases, a piston mechanism). In a manual inflator, the user’s effort pushes a piston or diaphragm, forcing air into a smaller volume. In electric inflators, an electric motor drives the compression.

Air Storage: Once the air is compressed, it is stored in a chamber or cylinder within the inflator, ready to be forced into the object being inflated.

Discharge: The compressed air is then discharged through a nozzle or valve into the object. As the air enters the object, it increases the internal pressure, causing the object to expand.

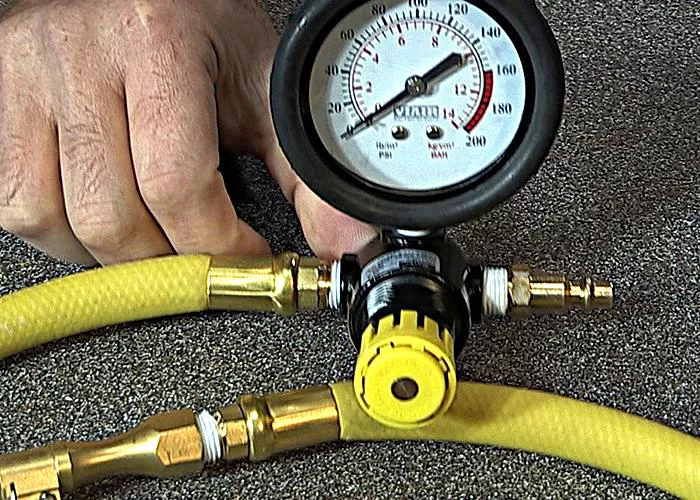

Pressure Control: Many inflators come equipped with a pressure gauge and control mechanisms that ensure the air pressure doesn’t exceed the recommended limits for the object being inflated.

Types of Compressor Mechanisms

The compressor is the key component of most inflators. Various types of compressors are used depending on the design of the inflator and its intended application.

Diaphragm Compressors: These compressors use a flexible diaphragm that moves up and down to compress air. They are commonly used in manual and small electric inflators. The diaphragm is usually made of rubber or a similar flexible material, and as it moves, it forces air into a chamber.

Piston Compressors: Piston compressors use a piston to compress air, and this mechanism is often found in larger electric inflators. The piston moves back and forth in a cylinder, compressing air into a high-pressure chamber. Piston compressors are capable of higher air flows and are used in applications requiring a more significant volume of air.

Rotary Compressors: These are more common in industrial-grade inflators and larger compressors used for vehicles and heavy machinery. Rotary compressor uses rotating elements, such as screws or gears, to compress air and can handle very high volumes and pressures.

Uses of Inflators

Inflators have a broad range of applications across various industries and everyday life. Some of the most common uses include:

Automotive Applications

The most common and essential use of inflators is in the automotive industry, specifically for inflating vehicle tires. Proper tire pressure is critical for vehicle safety, performance, and fuel efficiency. Under-inflated tires can cause poor handling, increased tire wear, and reduced fuel efficiency, while over-inflated tires can result in a harsh ride and increased risk of a blowout.

Inflators at gas stations or service centers are used to inflate tires to the manufacturer-recommended pressure, ensuring the vehicle runs safely and efficiently. Many modern vehicles come with built-in tire inflation systems that alert the driver when tire pressure is low, and portable inflators are available for personal use.

Sports and Recreation

Inflators are also widely used in sports and recreational activities. Many sports, including basketball, soccer, football, and volleyball, require inflated balls to be functional. Inflators are used to pump air into these balls, ensuring they reach the correct pressure for optimal performance.

Similarly, inflators are used for inflatable boats, rafts, and even air mattresses for camping or travel. These devices make it easy to inflate such equipment quickly and with minimal effort, ensuring a comfortable and functional outdoor experience.

Safety and Emergency Equipment

Inflators are vital in the context of safety equipment such as life jackets, air bags, and inflatable shelters. Life jackets, for example, need to be inflated quickly in emergencies to provide buoyancy and keep individuals safe. Inflators are used to quickly fill the chambers of life jackets with air in seconds, enabling them to perform their function when needed.

Airbags in vehicles are another important safety application. Airbag inflators use compressed gas or propellants to rapidly inflate the airbag in the event of a collision, providing a cushion to protect the passengers.

Industrial Applications

In industrial settings, inflators are used to fill large tires, airbags, and inflatable structures, as well as for specific manufacturing processes requiring precise pressure control. These industrial inflators are capable of achieving extremely high air pressures and flow rates, ensuring the rapid inflation of large items.

Technological Innovations in Inflators

Modern inflators come equipped with a range of features that enhance their functionality and ease of use. Some key innovations include:

Digital Pressure Gauges: Many electric inflators now come with built-in digital pressure gauges that allow users to set the desired pressure level. The inflator will automatically shut off when the target pressure is reached, preventing over-inflation.

Automatic Shut-Off: As mentioned above, this feature allows users to set the exact pressure they need, and the inflator will stop pumping once that pressure is achieved, reducing the risk of damage to the inflated object.

Cordless and Rechargeable Models: Many new inflators are designed to be portable and cordless, powered by rechargeable lithium-ion batteries. These models are convenient for use in various situations without being tethered to a power outlet.

Multi-Purpose Nozzles and Attachments: Some inflators come with interchangeable nozzles and attachments to handle different types of inflation tasks, including sports balls, inflatable toys, and even air mattresses.

Conclusion

In conclusion, inflators are essential tools used to increase the internal pressure of various objects, ranging from vehicle tires to sports equipment and safety devices. Their operation relies on fundamental mechanical principles of air compression, and they come in a variety of forms, from manual hand pumps to advanced electric inflators and CO2 cartridges. Understanding the working mechanism of inflators and their uses is crucial for maintaining the safety, functionality, and performance of the objects they inflate. With continued technological advancements, inflators will only become more efficient, portable, and user-friendly, further expanding their range of applications across industries and everyday life.