The V12 engine is a type of internal combustion engine that has twelve cylinders arranged in two banks of six, typically at a 60-degree angle to each other. It is widely regarded as a symbol of high-performance engineering, often found in luxury cars, sports cars, and exotic vehicles. The V12 engine has become synonymous with power, smoothness, and sophistication, offering an incredible balance between performance and refinement. But what exactly is it, and how does it function?

Understanding the V12 Engine Configuration

To understand the V12 engine’s operation, it is essential to first look at its basic configuration. The “V” shape refers to the arrangement of the engine’s cylinders, which are divided into two banks. These banks are typically arranged in a V formation, which gives the engine its name. The angle between these two banks is most commonly 60 degrees, but it can vary in some designs. The 12 cylinders in the engine allow for a higher power output and smoother operation than smaller engines.

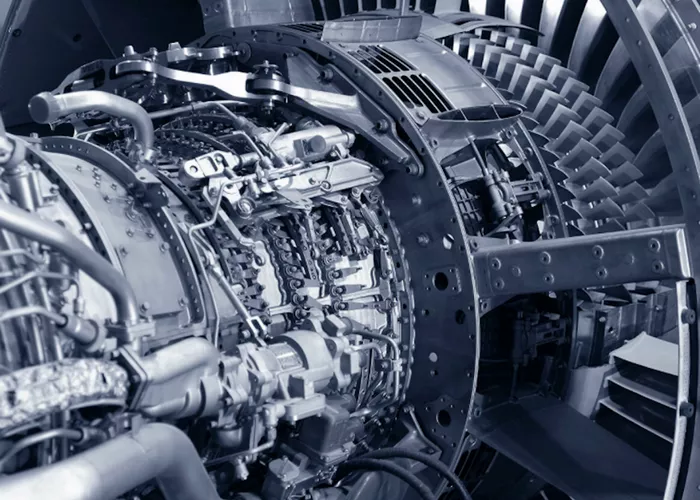

Components of a V12 Engine

Like all internal combustion engines, a V12 engine consists of several critical components that work together to create power. These include:

- Cylinders: The 12 cylinders are the heart of the V12 engine. They house the pistons that move up and down to create power through the combustion process.

- Pistons: The pistons are connected to the crankshaft and move within the cylinders. The pistons compress the fuel-air mixture and generate the necessary power to turn the crankshaft.

- Crankshaft: The crankshaft is a long metal rod that transforms the up-and-down motion of the pistons into rotational motion, which ultimately powers the vehicle.

- Valves and Camshafts: The V12 engine features intake and exhaust valves, which are controlled by the camshafts. These components regulate the intake of air and fuel and the expulsion of exhaust gases from the cylinders.

- Fuel Injectors: The fuel injectors deliver the right amount of fuel to each cylinder, allowing for optimal combustion.

- Ignition System: The spark plugs ignite the fuel-air mixture in the cylinders to create the combustion process.

- Lubrication and Cooling System: The engine is equipped with a lubrication system to keep moving parts lubricated and a cooling system to prevent the engine from overheating.

How the V12 Engine Works

Like any internal combustion engine, the V12 engine relies on the four-stroke cycle to produce power. This cycle consists of four phases: intake, compression, power, and exhaust. Here’s how the process works in detail:

1. Intake Stroke

During the intake stroke, the intake valve opens, and the piston moves down in the cylinder. This movement creates a vacuum that draws in a mixture of air and fuel from the intake manifold.

2. Compression Stroke

After the intake valve closes, the piston moves upward, compressing the air-fuel mixture. This increases the pressure and temperature inside the cylinder, preparing it for ignition.

3. Power Stroke

Once the air-fuel mixture is compressed, the spark plug ignites it, causing combustion. The force of this combustion drives the piston downward, generating the power that turns the crankshaft.

4. Exhaust Stroke

Finally, the exhaust valve opens, and the piston moves upward again, pushing the burnt gases out of the cylinder and into the exhaust system.

This process occurs in each of the V12’s 12 cylinders, with each cylinder firing at different times, ensuring that the engine runs smoothly and continuously. The V12 engine’s firing order and the way the cylinders work together result in a very smooth operation compared to other engine configurations, such as the Inline-6 Engine.

Advantages of the V12 Engine

The V12 engine offers several distinct advantages that make it popular in high-performance applications. Some of these advantages include:

1. Smoothness and Balance

One of the most notable features of a V12 engine is its exceptional smoothness. The engine is naturally balanced due to the even firing order and the fact that the V-shape allows for each piston to counterbalance the movement of the others. This results in minimal vibrations and a smooth, refined driving experience, which is particularly desirable in luxury vehicles and sports cars.

2. Power and Performance

With 12 cylinders, the V12 engine can produce significantly more power than smaller engines. The additional cylinders allow for a larger displacement, meaning the engine can burn more fuel and air mixture to generate more power. This makes the V12 engine ideal for high-performance cars, luxury vehicles, and sports cars that require both high horsepower and torque for acceleration and top speed.

3. High Revving Capability

V12 engines are capable of achieving high revolutions per minute (RPM). This is due to the engine’s smoothness and the ability of the components to handle high-speed operation. High-revving engines are often preferred in performance vehicles as they provide quicker acceleration and more responsive driving characteristics.

4. Prestige and Engineering Excellence

Owning a vehicle with a V12 engine often signifies a level of prestige and engineering excellence. This engine configuration is typically used in high-end, exotic vehicles such as Ferrari, Lamborghini, and Rolls-Royce. For many car enthusiasts, the V12 engine represents the pinnacle of automotive engineering.

Challenges and Disadvantages of the V12 Engine

Despite its many advantages, the V12 engine also has some challenges and disadvantages that limit its widespread use. These include:

1. Size and Weight

The V12 engine is large and heavy due to the additional cylinders and the need for stronger components to handle the extra power. This can increase the weight of the vehicle, potentially affecting its handling and fuel efficiency.

2. Fuel Consumption

With 12 cylinders, a V12 engine tends to consume more fuel than smaller engines. This is a significant drawback in terms of fuel efficiency, especially in an era where fuel economy is a growing concern. As such, V12 engines are typically found in vehicles where performance and power take precedence over fuel economy.

3. High Production and Maintenance Costs

Manufacturing a V12 engine is complex and expensive. The cost of producing such an engine is higher than that of smaller engine configurations, leading to higher costs for vehicles equipped with V12s. Additionally, maintenance and repairs for a V12 engine can be costly, requiring specialized knowledge and parts.

V12 Engines in Modern Vehicles

Despite the challenges, the V12 engine remains a popular choice for manufacturers of high-end luxury and performance vehicles. It is still commonly found in some of the most prestigious automotive brands, including:

- Ferrari: Ferrari’s V12 engines have become iconic, powering models such as the Ferrari 812 Superfast and the Ferrari LaFerrari hybrid supercar.

- Lamborghini: Lamborghini has long used V12 engines in its flagship models, including the Aventador and Murciélago.

- Rolls-Royce: The British luxury manufacturer has utilized V12 engines in models like the Rolls-Royce Phantom, offering a blend of power, luxury, and refinement.

- Aston Martin: Aston Martin’s V12 engine powers several of its high-performance models, including the DBS Superleggera.

Even though the V12 engine is less common in mainstream vehicles, its presence in the world of performance cars is undeniable. It provides unmatched performance and a unique driving experience that is hard to replicate with smaller engines.

Conclusion

The V12 engine remains one of the most prestigious and powerful engine configurations in the world of automobiles. Known for its smooth operation, exceptional power output, and refined performance, the V12 has earned its place in luxury and performance vehicles. While it faces challenges such as fuel consumption and high production costs, it continues to capture the imagination of car enthusiasts worldwide.