Linear potentiometers, often referred to as “linear position sensors” or simply “linear pots,” are precision devices used for measuring linear displacement. They are widely used in various industrial, automotive, aerospace, and consumer applications due to their high accuracy, repeatability, and ease of integration. Understanding the working principles and uses of linear potentiometers is essential for engineers, technicians, and designers who work with position feedback systems.

1. What is a Linear Potentiometer?

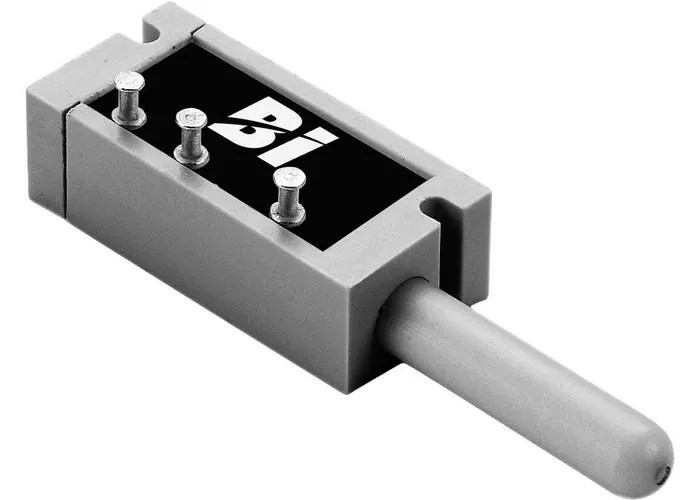

A linear potentiometer is an electromechanical transducer that converts linear motion or position into a corresponding electrical signal. Essentially, it functions as a variable resistor, where the resistance value changes based on the position of a sliding contact (wiper) along a resistive element. This electrical variation can be measured and translated into displacement data, making the device ideal for real-time position tracking.

Unlike rotary potentiometers that measure angular displacement, linear potentiometers are designed to detect straight-line movements. They are commonly found in applications that require precise measurement and control of movement over a defined linear range.

2. Components of a Linear Potentiometer

A linear potentiometer consists of several key components:

- Resistive Element: A strip of material with a known resistance value, usually made from carbon, cermet, or conductive plastic.

- Wiper (Sliding Contact): A movable contact that slides along the resistive element and varies the output voltage based on its position.

- Housing: Encases the internal components and protects them from environmental damage.

- Electrical Terminals: Includes two fixed terminals at the ends of the resistive element and one variable terminal connected to the wiper.

These components work together to provide a voltage divider circuit that outputs a voltage proportional to the position of the wiper.

3. How Linear Potentiometers Work

The operation of a linear potentiometer is based on the voltage divider principle. When a constant voltage is applied across the two fixed terminals of the resistive element, the voltage at the wiper (third terminal) varies linearly as the wiper moves along the element.

The output voltage (Vout) can be calculated using the formula:

Vout = (Position/Total Length) x Supply Voltage

Where:

- Position is the location of the wiper along the resistive element

- Total Length is the full length of the resistive track

- Supply Voltage is the voltage applied across the fixed terminals

This proportional relationship allows for accurate measurement of linear displacement.

4. Types of Linear Potentiometers

There are several types of linear potentiometers, each designed for specific use cases:

Wire-Wound Linear Potentiometers

- Use a wire-wound resistive element.

- Offer high accuracy but are limited in resolution and wear over time.

Plastic Film Linear Potentiometers

- Use conductive plastic materials.

- Offer better durability and resolution.

Cermet Linear Potentiometers

- Made from ceramic and metal composites.

- Offer excellent stability and temperature tolerance.

Digital Linear Potentiometers

- Use digital signals instead of analog.

- Suitable for integration with microcontrollers and digital systems.

5. Advantages of Using Linear Potentiometers

Linear potentiometers offer several benefits that make them suitable for a wide range of applications:

- High Accuracy and Precision: Enables reliable position tracking.

- Simple Integration: Easy to connect to analog and digital systems.

- Cost-Effective: Generally more affordable than alternative position sensors.

- Wide Measurement Range: Available in various lengths to suit different needs.

- Low Power Consumption: Ideal for battery-operated devices.

These advantages make them an ideal choice for engineers seeking reliable linear displacement measurement.

6. Limitations and Considerations

Despite their advantages, linear potentiometers also come with certain limitations:

- Wear and Tear: Mechanical contact between the wiper and resistive element can degrade over time.

- Sensitivity to Contaminants: Dust, moisture, and chemicals can affect performance.

- Linearity Errors: Some models may not provide perfectly linear output.

- Temperature Sensitivity: Performance can vary with temperature fluctuations.

Proper housing and environmental sealing can mitigate many of these issues.

7. Applications of Linear Potentiometers

Linear potentiometers are used in a wide array of applications, including:

Automotive Industry

- Throttle position sensing

- Suspension systems

- Brake and clutch position monitoring

Industrial Automation

- Robotics

- CNC machines

- Conveyor systems

Aerospace and Defense

- Flight simulators

- Actuator position feedback

Medical Equipment

- Hospital beds

- Surgical devices

Consumer Electronics

- Gaming controllers

- Audio equipment

These diverse applications highlight the adaptability and utility of linear potentiometers in modern engineering.

8. Installation and Maintenance

Proper installation and maintenance are crucial for the reliable performance of linear potentiometers:

- Mounting: Ensure correct alignment with the direction of movement.

- Electrical Connection: Use shielded cables to minimize noise.

- Environmental Protection: Apply seals or enclosures in harsh environments.

- Routine Inspection: Check for signs of wear, corrosion, or misalignment.

Following these guidelines can extend the lifespan and maintain the accuracy of the sensor.

9. Calibration and Testing

Calibration ensures the output of the linear potentiometer accurately reflects the actual displacement:

- Initial Setup: Apply known displacements and record output voltages.

- Data Plotting: Compare the actual vs. measured values.

- Adjustment: Tweak the setup to minimize deviations.

Regular testing and recalibration are recommended, especially in critical applications.

Conclusion

Linear potentiometers are indispensable tools in many engineering fields due to their simplicity, accuracy, and cost-effectiveness. By converting linear motion into a measurable electrical signal, they offer real-time feedback crucial for automation, control, and monitoring systems. While they have some limitations, proper selection, installation, and maintenance can significantly enhance their performance and longevity.

FAQs

Q1: What is the difference between a linear and rotary potentiometer?

A linear potentiometer measures straight-line movement, while a rotary potentiometer measures angular displacement.

Q2: How do I choose the right linear potentiometer for my application?

Consider factors like measurement range, environmental conditions, required accuracy, and interface compatibility.

Q3: Are linear potentiometers suitable for harsh environments?

Yes, if properly sealed and protected from contaminants, they can perform well in challenging conditions.

Q4: Can a linear potentiometer work with a microcontroller?

Absolutely. The analog voltage output can be read using an analog-to-digital converter (ADC) on most microcontrollers.

Q5: What are common failure modes of linear potentiometers?

Common issues include wear of the resistive element, misalignment, electrical noise, and environmental damage.

Q6: How often should linear potentiometers be calibrated?

Frequency depends on the application, but annual calibration is a good general guideline for maintaining accuracy.