Charge-Coupled Devices, commonly known as CCDs, have been pivotal in the advancement of imaging technology for decades. CCD array sensors, in particular, represent a class of devices that convert optical images into electronic signals with exceptional precision and quality. These sensors are foundational to various applications including digital photography, astronomy, machine vision, medical imaging, and industrial inspection systems.

Understanding the fundamental principles, architecture, and operational mechanisms of CCD array sensors provides insight into their enduring importance despite the advent of newer technologies such as CMOS image sensors. This article delves into what CCD array sensors are, their internal working mechanisms, the underlying physics, and their practical applications.

The Fundamentals of CCD Technology

What is a Charge-Coupled Device (CCD)?

A Charge-Coupled Device is a semiconductor device designed to capture and process light by converting photons into electrons and then moving those electrons through the sensor to be read out as a digital signal. Essentially, CCDs operate as arrays of tiny light-sensitive elements called pixels that gather photo-generated charge proportional to the light intensity falling upon them.

The “charge-coupled” term arises from the method by which these electrical charges are transferred across the device. Charges collected in each pixel are shifted sequentially through adjacent pixels until they reach an output amplifier, where they are converted into voltage signals for further processing.

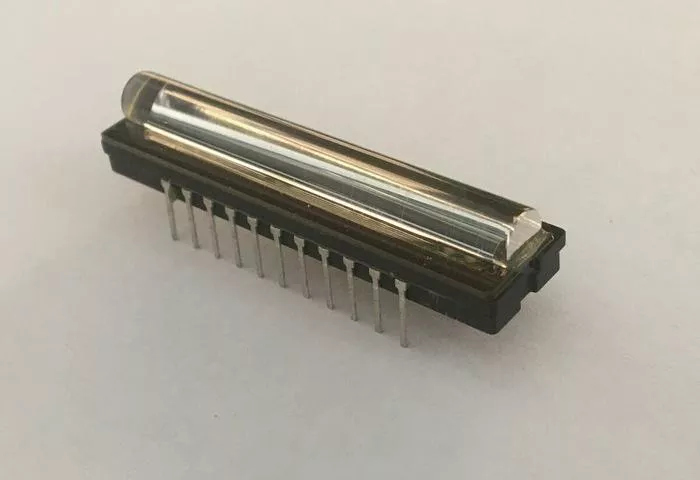

CCD Array Sensors Defined

CCD array sensors are a specific type of CCD designed in a matrix or linear configuration of photo-sensitive cells (pixels). A linear CCD array sensor captures one-dimensional information (such as scanning applications), while a two-dimensional CCD array sensor captures a complete two-dimensional image similar to a digital camera sensor.

The array format enables high spatial resolution and sensitivity because each pixel in the array acts as an individual photo-detector, allowing for the capture of detailed images with minimal noise.

Structure and Composition of CCD Array Sensors

Material Composition

CCDs are typically fabricated from high-purity silicon wafers using semiconductor manufacturing techniques. Silicon’s bandgap properties make it an excellent substrate for photo-detection in the visible and near-infrared spectrum.

The surface of the silicon is engineered to form an array of potential wells — small regions that can hold electrical charge. These wells correspond to the individual pixels on the sensor.

Pixel Architecture

Each pixel in a CCD sensor consists of a photodiode or a photogate that accumulates charge in response to incident photons. The amount of charge generated is proportional to the intensity of light that hits that pixel during the exposure time.

These pixels are arranged in a grid-like fashion, and their ability to accumulate and transfer charges without significant loss or distortion is the hallmark of CCD efficiency.

Charge Transfer Channels

Interspersed between the pixels are electrodes that create potential barriers and wells through controlled voltage signals. These potentials guide the charge packets across the sensor array to the readout register by a process known as “clocking.” The careful timing and voltage modulation allow the charges to shift smoothly without mixing or loss.

How CCD Array Sensors Work

Photon-to-Electron Conversion

The operation begins when light photons strike the sensor surface. Each photon that hits the silicon can excite an electron from the valence band into the conduction band, generating an electron-hole pair. The electrons are attracted to the positively biased potential wells of the pixels and accumulate as charge packets.

The accumulation of electrons over a controlled integration period forms a charge proportional to the light intensity on each pixel.

Charge Transfer Mechanism

Once the integration phase completes, the sensor initiates a sequential transfer of the charge packets. Through the manipulation of the voltage on the electrodes, charge packets are moved horizontally (in row-by-row fashion) towards the readout register.

In two-dimensional CCD arrays, charge transfer occurs first along columns to a horizontal shift register and then horizontally towards the output amplifier.

Signal Readout and Conversion

At the output stage, the charge packets are converted to voltage signals via a charge-to-voltage amplifier (often a floating diffusion amplifier). This analog voltage is then digitized through an analog-to-digital converter (ADC) to produce a digital image.

The process is repeated line-by-line until the entire array is read out.

Advantages of CCD Array Sensors

High Image Quality

CCD sensors are renowned for their high quantum efficiency — the ability to convert incoming photons into charge effectively. This translates into superior sensitivity and low noise levels, which is crucial for scientific and professional imaging.

Uniformity and Low Fixed-Pattern Noise

The architecture of CCDs facilitates uniform charge transfer and amplification, minimizing fixed-pattern noise that can distort images. This results in cleaner, more accurate images especially in low-light conditions.

Low Dark Current

CCD arrays exhibit relatively low dark current — the charge generated in absence of light — due to their fabrication techniques and cooling methods. This enhances their performance in long-exposure applications like astrophotography.

Limitations of CCD Array Sensors

Power Consumption

Due to the high voltage clocking and the charge transfer process, CCD sensors typically consume more power than CMOS sensors. This can limit their use in battery-operated devices.

Speed Constraints

The serial readout nature of CCDs means that image acquisition speed is generally slower compared to parallel CMOS sensors, which can read multiple pixels simultaneously.

Manufacturing Complexity and Cost

CCD sensors require more complex fabrication processes and specialized support electronics, which often translates into higher costs relative to CMOS alternatives.

Applications of CCD Array Sensors

Scientific and Industrial Imaging

CCD sensors excel in environments demanding high precision and sensitivity, such as telescopes for astronomy, electron microscopy, and spectrometry. Their ability to capture low-light images with minimal noise is invaluable.

Medical Imaging

In medical diagnostics, CCD array sensors are used in devices like endoscopes and digital X-ray systems, where clear and accurate imaging is crucial for patient care.

Machine Vision and Quality Control

Automated inspection systems in manufacturing rely on CCD arrays for detailed imaging, enabling precise defect detection and quality assurance.

Consumer Electronics

Though increasingly supplanted by CMOS sensors in consumer devices, CCDs were once the dominant sensor technology in digital cameras due to their image quality and low noise characteristics.

Conclusion

CCD array sensors remain a cornerstone of imaging technology, prized for their exceptional image quality, sensitivity, and reliability. By converting light into electronic signals through sophisticated charge accumulation and transfer mechanisms, CCDs enable applications requiring high precision and low noise imaging.

While CMOS sensors have gained popularity due to their lower cost, faster speed, and integration capabilities, CCD technology continues to serve specialized fields where ultimate image fidelity is paramount. Understanding how CCD array sensors work sheds light on their enduring relevance and the engineering ingenuity behind their design.