Rotary potentiometers are essential components in both analog and digital electronic systems. They serve as variable resistors or voltage dividers, playing a pivotal role in controlling devices by adjusting voltage or current flow. From audio equipment to industrial machinery, their versatility and reliability make them indispensable in countless applications. Understanding how they work and their practical uses is crucial for engineers, technicians, and electronics enthusiasts alike.

1. What are Rotary Potentiometers

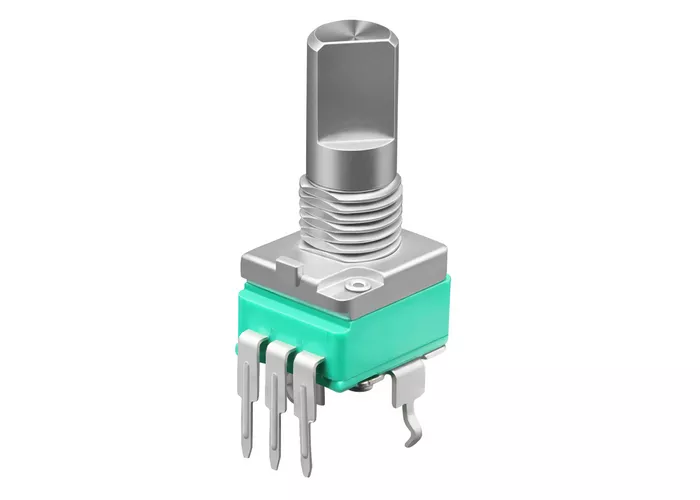

A rotary potentiometer is an electromechanical device that converts angular position or motion into a variable resistance. Typically, it comprises three main terminals: two fixed terminals connected to the ends of a resistive element and a third terminal connected to a wiper that slides along this element as the knob is turned.

- Fixed terminals: Connected to the ends of the resistive track.

- Wiper terminal: Moves along the track to vary the resistance.

- Shaft: The part that the user rotates, connected to the wiper.

As the shaft is rotated, the position of the wiper changes, thus altering the resistance between the wiper and each end terminal. This change enables the potentiometer to control voltage in a circuit.

2. How Rotary Potentiometers Work

The working principle of a rotary potentiometer revolves around the concept of resistance variation. The resistive element, usually made from carbon, cermet, or conductive plastic, provides a uniform resistance over its length. The wiper makes mechanical contact with this resistive path and divides it into two parts.

When voltage is applied across the two fixed terminals, the output voltage from the wiper depends on its position. If the wiper is at one end, it outputs nearly the same voltage as that terminal. If in the middle, it outputs about half, assuming a linear resistance distribution. The resistance changes linearly or logarithmically, depending on the design.

This principle makes rotary potentiometers useful for adjusting signal levels, such as in volume controls or light dimmers.

3. Types of Rotary Potentiometers

Rotary potentiometers come in various types to suit different applications. The most common classifications include:

Based on Taper

- Linear Taper (LIN): Resistance changes uniformly with the rotation angle.

- Logarithmic Taper (LOG): Resistance changes logarithmically, suitable for audio applications due to the logarithmic response of human hearing.

Based on Construction

- Carbon Composition: Inexpensive and common, but wear out faster.

- Wire-Wound: High power and precision applications, limited resolution.

- Cermet and Conductive Plastic: Offer better durability and precision.

Based on Configuration

- Single-turn: One rotation (usually 270 degrees).

- Multi-turn: Multiple turns for fine adjustments.

- Dual-gang or Multi-gang: Two or more potentiometers controlled by one shaft, often used in stereo audio systems.

Each type offers unique advantages depending on the application, environmental conditions, and precision requirements.

4. Applications of Rotary Potentiometers

Rotary potentiometers are widely used across various fields due to their simplicity and effectiveness. Their primary applications include:

- Audio Equipment: Volume controls, tone adjustments.

- Industrial Controls: Machine positioning, actuator feedback.

- Automotive: Throttle position sensors, dashboard dimmers.

- Consumer Electronics: Dimmers, control knobs for appliances.

- Medical Devices: Calibration and settings in diagnostic equipment.

In all these cases, the ability to finely tune electrical parameters makes potentiometers critical to achieving optimal performance and user interaction.

5. Advantages of Using Rotary Potentiometers

Rotary potentiometers offer several benefits that make them a popular choice for many applications:

- Simplicity: Easy to use and integrate into circuits.

- Cost-effective: Generally inexpensive compared to other control devices.

- Manual Control: Allows intuitive human-machine interface.

- Versatility: Available in numerous forms for different needs.

- Analog Signal Compatibility: Ideal for analog control systems.

These features make them suitable for both prototyping and production-scale designs.

6. Limitations and Considerations

Despite their benefits, rotary potentiometers have certain limitations that users should consider:

- Wear and Tear: Mechanical contact leads to eventual degradation.

- Limited Precision: Not suitable for applications requiring high-resolution feedback.

- Environmental Sensitivity: Dust and moisture can affect performance.

- Physical Size: Bulkier than some modern alternatives like digital encoders.

To address these issues, careful selection based on application requirements and environmental factors is essential.

7. Installation and Calibration Tips

Installing and calibrating rotary potentiometers properly ensures accurate and reliable operation. Follow these steps for optimal results:

- Positioning: Mount securely to prevent movement during operation.

- Wiring: Connect correctly to the circuit with reference to datasheets.

- Testing: Measure resistance or voltage output to verify functionality.

- Calibration: Adjust the potentiometer while monitoring system output.

- Protection: Use enclosures if needed to guard against environmental effects.

Improper installation can lead to erratic performance, so attention to detail is crucial.

8. Maintenance and Troubleshooting

Maintaining rotary potentiometers involves regular inspection and cleaning to prevent failure. Key maintenance tips include:

- Periodic Cleaning: Remove dust and debris using compressed air.

- Lubrication: Use contact cleaners or lubricants designed for electronics.

- Testing Continuity: Use a multimeter to check for smooth resistance change.

- Replacing Worn Units: If resistance is erratic or unstable, replacement is necessary.

Troubleshooting symptoms like dead spots, noise, or inconsistent output usually point to mechanical wear or contamination.

Conclusion

Rotary potentiometers remain vital components in modern electronics due to their simplicity, versatility, and effectiveness in controlling analog signals. Understanding their structure, working principles, and appropriate application ensures optimal performance and longevity. While alternatives exist, their cost-effectiveness and tactile feedback continue to make them a preferred choice in various industries.

FAQs

1. What is the difference between a rotary potentiometer and a digital encoder?

A rotary potentiometer changes resistance mechanically to vary voltage, while a digital encoder generates digital signals representing position. Encoders offer higher precision and are more durable in high-use environments.

2. Can rotary potentiometers be used in digital circuits?

Yes, rotary potentiometers can interface with analog-to-digital converters (ADCs) in microcontrollers to provide analog input to digital systems.

3. How long do rotary potentiometers typically last?

Their lifespan varies based on construction and usage. Carbon types may last tens of thousands of cycles, while high-end conductive plastic or wire-wound types can endure millions of operations.

4. What causes a potentiometer to fail?

Common causes include mechanical wear, dirt and debris, oxidation on contact surfaces, and excessive electrical loads.

5. Are rotary potentiometers waterproof?

Standard potentiometers are not waterproof. However, sealed or IP-rated models are available for harsh environments.

6. Can I replace a rotary potentiometer with a digital one?

Yes, but you’ll need a compatible interface (like an SPI or I2C bus) and firmware support. It changes the nature of control from analog to digital.

7. What materials are used in the resistive element of rotary potentiometers?

Common materials include carbon, cermet (ceramic-metal composite), conductive plastic, and wire-wound elements, each offering different characteristics in terms of durability, resistance range, and temperature stability.