Array sensors are specialized devices that consist of an arrangement of multiple individual sensing elements or sensors, typically used to detect and measure various physical phenomena like temperature, pressure, sound, light, or even mechanical stress. These sensors are often used in applications requiring a broad spatial detection range or the ability to capture complex data sets with high precision and speed.

Array sensors have become essential components in many advanced systems, particularly in fields such as robotics, environmental monitoring, automotive technologies, and medical devices. They are integral to applications like imaging systems, proximity sensing, and gesture recognition. The ability to detect, process, and respond to stimuli over a wide area makes them crucial for next-generation technologies.

What Are Array Sensors

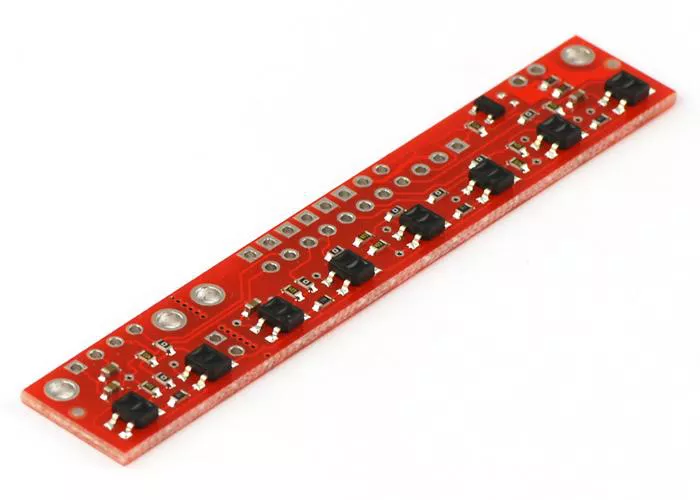

An array sensor typically consists of a grid or matrix of sensing elements, each capable of independently detecting the desired physical parameter. These sensors are organized in rows and columns, enabling them to cover a significant area or detect variations across a broad spectrum. The array can consist of a variety of sensor types, such as infrared sensors, vibration sensors, or pressure sensors, depending on the application.

Array sensors are designed to improve the performance of systems by providing more comprehensive and accurate data compared to single-point sensors. In some cases, they can be arranged in a way that mimics human sensory systems, allowing them to detect more subtle or complex changes in the environment.

How Do Array Sensors Work

The working principle of array sensors depends on the type of sensor element used in the array. However, the general concept remains similar across various types of array sensors. Here is an overview of how array sensors work in various applications:

Optical Array Sensors

Optical array sensors work by capturing light from a scene through multiple individual optical sensing elements arranged in an array format. These sensors can detect the intensity, color, and spectrum of light. They are commonly used in cameras and imaging devices, where each pixel in the sensor array captures light, forming a complete image. Each pixel is essentially a sensor in its own right, measuring the incoming light and converting it into a digital signal for processing.

Infrared Array Sensors

Infrared array sensors are designed to detect infrared radiation, which is emitted by objects in the form of heat. These sensors are used in thermal cameras and other heat sensing applications. The sensor array detects temperature variations across the surface it is observing. By comparing the emitted infrared radiation from different parts of the array, the system can create a thermal map of the observed area. These sensors are also useful in applications such as safety and security, where they detect heat signatures, such as body heat from intruders. Infrared sensors play a critical role in detecting thermal anomalies in industrial systems as well.

Pressure Array Sensors

Pressure array sensors detect pressure variations across a range of locations. These sensors are used in environments where pressure changes need to be monitored over a large area. For instance, in manufacturing or processing plants, a pressure sensor array can detect leaks or irregularities in pressure distribution. The array works by measuring the pressure at various points and then transmitting the data to a central system for analysis. This type of sensor is often used in the automotive industry to monitor tire pressure and in industrial systems for detecting fluid or gas pressure variations. Pressure sensors are essential components for maintaining safety and efficiency in many critical systems.

Flow and Vibration Array Sensors

Flow sensors measure the flow rate of liquids or gases through a pipe or conduit. When used in an array, multiple flow sensors can provide real-time data over a large area or system. This allows for monitoring and controlling flow rates in various applications, from HVAC systems to industrial processes. Similarly, vibration sensors detect mechanical vibrations and movements. When multiple vibration sensors are used in an array, they can provide a detailed understanding of the vibrations across a system or machine, which is valuable for predictive maintenance and system diagnostics. Flow sensors are increasingly being used in fluid dynamics studies and system performance analysis.

Types of Array Sensors

Array sensors come in a variety of types based on the physical phenomena they detect. Some of the most common types of array sensors include:

1. Thermal Array Sensors

Thermal array sensors are designed to detect heat patterns and temperature variations in a given area. These sensors work by using infrared technology to detect heat emissions from objects or environments. They are typically used in applications such as thermal imaging, fire detection, and medical diagnostics. By analyzing the heat map generated by the sensor array, operators can detect issues like equipment overheating or abnormal temperature distributions in machinery.

2. Pressure Array Sensors

Pressure array sensors are used to monitor pressure changes across a system or surface. The array can consist of piezoelectric or capacitive sensors arranged in a grid to measure the pressure at multiple points. These sensors are commonly used in hydraulic systems, aerospace engineering, and process control. In automotive applications, pressure array sensors are used to monitor the tire pressure of vehicles, ensuring safe operation.

3. Light Array Sensors

Light array sensors consist of multiple photodetectors arranged in an array, with each sensor detecting the intensity of light at a specific point. These sensors are used in applications such as optical imaging, industrial automation, and environmental monitoring. By capturing light intensity variations across the array, the sensor can generate a detailed image or map of the illuminated area.

4. Ultrasonic Array Sensors

Ultrasonic array sensors are used for detecting objects, measuring distances, and analyzing surface profiles using high-frequency sound waves. The array consists of multiple ultrasonic transducers, each emitting and receiving sound waves. When these sound waves bounce off surfaces, they return to the sensor, and the time it takes for the sound to return is used to calculate the distance. Ultrasonic array sensors are used in a variety of applications, including robotics, automotive parking sensors, and industrial level measurement systems. Ultrasonic transducers are particularly valuable for non-contact sensing in hazardous environments.

Applications of Array Sensors

Array sensors are utilized in a wide range of industries and applications. Their ability to capture detailed data over a large area makes them ideal for use in complex systems. Some notable applications include:

1. Imaging and Surveillance Systems

One of the most common applications for array sensors is in imaging and surveillance systems. Whether it’s infrared imaging, visible light imaging, or thermal imaging, array sensors provide high-resolution data to capture detailed images and videos. These sensors are used in security cameras, military surveillance systems, and medical diagnostic tools like thermography scanners.

2. Automotive Industry

In the automotive industry, array sensors are used for various purposes, including monitoring vehicle systems, detecting environmental conditions, and assisting with advanced driver-assistance systems (ADAS). For example, radar arrays are used for collision detection and adaptive cruise control, while pressure arrays monitor tire conditions. Additionally, ultrasonic array sensors assist with parking sensors by detecting obstacles around the vehicle.

3. Industrial and Process Monitoring

Array sensors are critical in industrial applications for monitoring machinery, process control, and environmental conditions. Vibration arrays help in detecting abnormal vibrations in machinery, which could be a sign of wear or impending failure. Pressure sensor arrays monitor fluid systems for leaks or irregularities. Flow sensors are used to ensure the proper flow of liquids and gases in pipelines, preventing blockages and system inefficiencies.

4. Robotics and Automation

Array sensors are extensively used in robotics and automation to enable robots to perceive their environment and respond to stimuli. These sensors are used in vision systems, touch sensors, and proximity detection systems. By using multiple sensing elements in an array, robots can improve their perception, spatial awareness, and ability to perform complex tasks autonomously.

Advantages and Limitations of Array Sensors

Like any technology, array sensors have both advantages and limitations that must be considered when deciding whether they are appropriate for a particular application. Below are some key benefits and drawbacks of using array sensors:

Advantages

- High Spatial Resolution: By using an array of sensors, the system can capture detailed spatial data, allowing for more precise measurements across a large area.

- Simultaneous Detection: Multiple sensors in the array can detect different points of interest simultaneously, leading to faster data collection and processing.

- Versatility: Array sensors can be designed to detect a wide range of physical parameters, such as light, pressure, temperature, and sound, making them versatile tools in many fields.

- Redundancy: Since multiple sensors are involved, array sensors provide redundancy, which helps in ensuring reliability and fault tolerance in critical systems.

Limitations

- Complexity: The design, calibration, and maintenance of array sensors can be complex, especially when dealing with large arrays of sensitive elements.

- Cost: Array sensors, particularly those designed for specialized applications, can be expensive to produce and maintain.

- Data Overload: Due to the large amount of data generated by multiple sensors, managing and processing this data can be challenging, requiring advanced software and processing power.

Conclusion

Array sensors have become a cornerstone in various industries, providing unparalleled versatility and precision in detecting and measuring physical phenomena. With their ability to cover large areas and provide high-resolution data, these sensors play a pivotal role in applications ranging from robotics to environmental monitoring. As technology continues to evolve, array sensors will undoubtedly become even more integral to modern systems, driving innovations in automation, safety, and diagnostics.