A pulse transformer is a specialized type of transformer designed to transmit electrical pulses with high accuracy and minimal distortion. Unlike traditional transformers, which are primarily designed for continuous alternating current (AC) signals, pulse transformers are engineered to handle brief, high-energy bursts of electricity. These electrical pulses are commonly used in a wide range of applications, including digital circuits, telecommunications, radar systems, and medical equipment such as defibrillators. The key challenge in designing pulse transformers is to ensure that the pulse energy is transferred effectively without distortion, as even minor variations can lead to significant issues in sensitive systems.

How Do Pulse Transformers Work

The fundamental operation of a pulse transformer is based on the principles of electromagnetic induction, similar to that of any other transformer. However, the difference lies in how the transformer responds to pulses rather than continuous signals. When a high-voltage pulse is applied to the primary coil, it induces a corresponding voltage in the secondary coil. The design of the transformer must ensure that the pulse signal is transmitted accurately, with minimal loss or distortion. The transformer must handle high-speed transitions between the “on” and “off” states to preserve the integrity of the pulse.

Key Components of Pulse Transformers

A pulse transformer consists of several critical components, each playing a vital role in its function:

Primary Coil

The primary coil is where the input pulse is applied. It is typically wound with a wire that has the necessary insulation and resistance to handle high-speed electrical signals. The size and material of the wire are chosen based on the transformer’s application, ensuring that the coil can handle the required pulse energy without overheating or causing signal degradation.

Secondary Coil

The secondary coil is responsible for receiving the pulse signal and transmitting it to the load. The number of turns in the secondary coil relative to the primary coil determines the voltage transformation ratio. For pulse transformers, the turns ratio is often carefully chosen to minimize signal distortion and match the impedance of the circuit the transformer is connected to.

Magnetic Core

The magnetic core of a pulse transformer is a crucial element in ensuring efficient energy transfer. The core material is typically composed of ferrite or iron, materials that provide high magnetic permeability to minimize energy loss. In pulse transformers, the core must be designed to handle the rapid transitions in current associated with pulsed signals without saturating. Saturation can cause signal distortion or loss of signal integrity, so careful material selection and core design are essential for optimal performance.

Insulation

Pulse transformers operate under high voltage conditions, so proper insulation is critical to prevent electrical breakdown and ensure safe operation. The insulation material used in pulse transformers must withstand both the high voltages and fast switching times associated with pulse signals. Materials such as polyimide, Teflon, and epoxy resins are commonly used to provide the necessary insulation while also offering good dielectric properties for high-frequency pulses.

Characteristics of Pulse Transformers

Pulse transformers possess several distinctive characteristics that differentiate them from traditional transformers:

High Bandwidth and Fast Response Time

Pulse transformers must be capable of transmitting signals with fast rise times and high frequencies. These characteristics are essential for applications such as radar systems, where the ability to generate and transmit high-speed pulses is critical. The bandwidth of a pulse transformer is determined by its core material, winding configuration, and the overall design of the transformer. To achieve high bandwidth, pulse transformers often use materials with low core losses and low hysteresis to minimize signal distortion during transmission.

Low Leakage Inductance

Leakage inductance refers to the portion of the magnetic flux that does not link the primary and secondary coils. High leakage inductance can result in poor energy transfer efficiency and signal distortion, especially in high-speed pulse applications. Pulse transformers are typically designed to minimize leakage inductance, ensuring that the majority of the magnetic flux is transferred between the primary and secondary coils, thus enhancing the efficiency and performance of the transformer.

High Efficiency in Pulse Transmission

Pulse transformers are designed to efficiently transmit short-duration, high-voltage pulses with minimal power loss. This is crucial in applications where every fraction of the pulse’s energy must be delivered to the load. Efficient transmission is particularly important in communication systems, where signal integrity must be maintained over long distances or through complex networks.

Low Distortion in Signal Transmission

One of the primary concerns when designing pulse transformers is minimizing signal distortion. Distorted pulses can lead to errors in the systems relying on them, such as miscommunication in digital circuits or inaccurate results in medical equipment. Pulse transformers are carefully engineered to preserve the shape and timing of the pulses, ensuring that they are transmitted with minimal distortion. This often involves optimizing the transformer’s core material, winding configuration, and impedance matching.

Applications of Pulse Transformers

Pulse transformers are utilized in a wide variety of industries, including telecommunications, medical devices, industrial equipment, and military applications. Below are some of the primary uses of pulse transformers:

Communication Systems

In communication systems, pulse transformers are used to transmit digital signals, modulated signals, or high-speed data. The ability to handle high-frequency pulses with low distortion is essential for maintaining the integrity of transmitted information. Pulse transformers are commonly used in both wired and wireless communication systems, including telephone networks, fiber optics, and satellite communications.

Radar and Electronic Warfare

Pulse transformers play a critical role in radar and electronic warfare systems. In radar systems, pulse transformers are used to generate and transmit high-energy pulses that bounce off objects and return to the radar receiver. The time delay of the returning pulse is then used to calculate the distance and speed of objects. In electronic warfare, pulse transformers help generate the high-power pulses needed for jamming or countermeasure operations.

Medical Equipment

Pulse transformers are essential in medical devices that rely on high-voltage electrical pulses for operation. One of the most notable applications is in defibrillators, which use electrical pulses to restore normal heart rhythms in patients suffering from arrhythmias. The ability of pulse transformers to provide precise and controlled pulses is crucial for the effective operation of these life-saving devices.

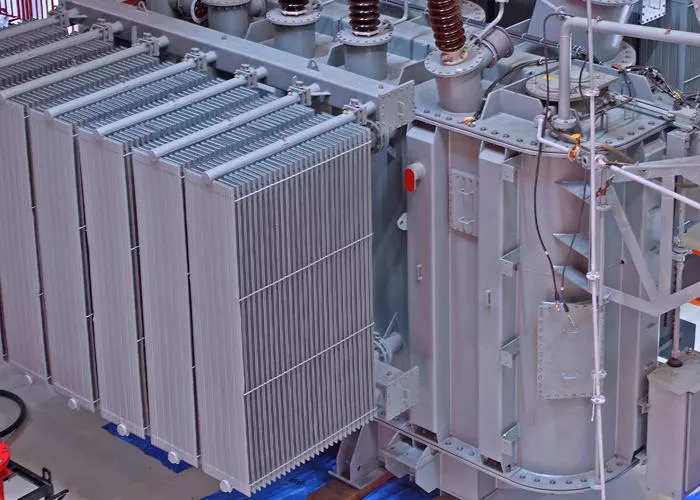

High-Voltage Power Systems

In power systems, pulse transformers are sometimes used for voltage regulation and electrical isolation. They are particularly useful in high-voltage systems that require precise pulse-based control, such as in the case of pulse width modulation (PWM) used for controlling power converters and inverters. Pulse transformers help isolate different sections of the power system to prevent damage from voltage spikes and surges.

Industrial Applications

Pulse transformers are also used in industrial applications that involve high-speed signaling or switching. For example, in manufacturing processes, pulse transformers are used to control the timing of automated machines, synchronize equipment, or send diagnostic signals for monitoring machine performance. They are also used in testing equipment to simulate real-world operating conditions or in power distribution systems to protect against electrical faults.

Design Considerations for Pulse Transformers

Designing pulse transformers requires careful consideration of several factors to ensure optimal performance. Some of the key design parameters include:

Core Material Selection

The choice of core material is crucial in the design of pulse transformers. Materials with high magnetic permeability, such as ferrite or amorphous steel, are often used to minimize losses and maximize the efficiency of pulse transmission. The core material also needs to be able to handle the high-speed transitions in current without saturating, as saturation can lead to signal distortion.

Winding Configuration

The winding configuration affects the impedance matching, leakage inductance, and the overall efficiency of the transformer. For pulse transformers, a tightly wound coil is often used to reduce leakage inductance and improve the speed at which the transformer can respond to rapid changes in current. The winding geometry is also designed to minimize any parasitic capacitance that could affect high-frequency performance.

Impedance Matching

Impedance matching is an essential consideration in the design of pulse transformers to ensure that the signal is transferred with minimal reflection and energy loss. The transformer’s primary and secondary windings must be designed to match the impedance of the source and load, respectively, to optimize performance and reduce signal distortion. Failure to match impedance can result in signal reflections, which can distort the pulse signal and degrade system performance.

Voltage and Current Ratings

Pulse transformers must be designed to handle the specific voltage and current ratings required for the application. The insulation, wire gauge, and core material must be chosen to ensure the transformer can withstand the high-voltage pulses without breaking down or experiencing excessive losses. In applications such as defibrillators or radar systems, pulse transformers must be capable of handling voltages in the range of thousands of volts.

Challenges in Pulse Transformer Design

Despite their versatility, pulse transformers come with several challenges during the design process:

High-Frequency Operation

As pulse transformers are required to operate at high frequencies, they face the challenge of maintaining efficiency and minimizing losses at these speeds. High-frequency operation can introduce parasitic capacitances and inductances, which can degrade performance and distort the transmitted pulse. Engineers must carefully design the transformer to minimize these effects, often employing advanced materials and winding techniques to achieve the desired results.

Minimizing Core Saturation

Core saturation occurs when the magnetic field in the core material becomes too strong, causing the core to lose its ability to support further changes in the magnetic field. This can lead to distortion and loss of signal integrity. To prevent saturation, pulse transformers are designed with cores that have high saturation points or are carefully sized to ensure they operate within the linear region of the core material.

Thermal Management

Pulse transformers generate heat due to the rapid switching of electrical currents. Managing this heat is critical to preventing damage to the transformer and maintaining optimal performance. Designers must consider heat dissipation methods, such as using heat sinks or choosing materials with high thermal conductivity, to keep the transformer within safe operating temperatures.

Conclusion

Pulse transformers play a vital role in a variety of industries, offering reliable and precise transmission of electrical pulses for applications ranging from communication systems to medical devices. Their ability to handle high-frequency signals with minimal distortion and loss makes them indispensable for systems that require high-speed, accurate pulse transmission. With ongoing advancements in material science and transformer design, pulse transformers continue to evolve to meet the increasingly complex demands of modern technology.