Planar transformers have become increasingly popular in the modern electrical engineering industry due to their compact size, high efficiency, and versatility. These transformers offer distinct advantages in various applications, including power electronics, telecommunications, and consumer electronics. This article provides a detailed understanding of planar transformers, their construction, operation, benefits, and real-world applications. Through a careful exploration, we aim to highlight the innovative features that make planar transformers a key component in modern power systems.

What Are Planar Transformers

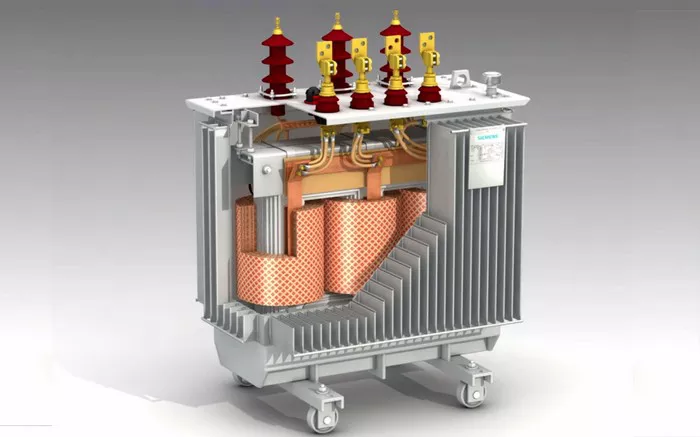

A transformer is a device that transfers electrical energy between two or more circuits through electromagnetic induction. Traditional transformers use wound copper coils around a magnetic core, while planar transformers represent a novel approach to transformer design. Planar transformers use flat, printed circuit board (PCB)-based windings that allow for a more compact and efficient design compared to their conventional counterparts. This unique structure is key to the planar transformer’s efficiency, heat management, and integration capabilities in space-constrained environments.

Planar transformers are often employed in applications where the reduction of size and weight is critical, such as in portable electronics, renewable energy systems, and electric vehicles. With the growing demand for more efficient and miniaturized electronic devices, planar transformers have proven themselves as an essential component in meeting these requirements.

Understanding the Construction of a Planar Transformer

The construction of a planar transformer differs significantly from that of traditional transformers, which typically feature coil windings wrapped around a core. Instead of using cylindrical windings, a planar transformer utilizes flat, layered windings that are etched onto a PCB substrate. This design provides several advantages, including lower profile, better thermal management, and the ability to integrate with other circuit components on the same PCB.

Core Materials and Design

Like traditional transformers, planar transformers require a core material that supports magnetic flux and allows energy transfer between the primary and secondary windings. The core of a planar transformer is typically made of ferrite or other magnetic materials, depending on the application’s frequency range and power requirements. The core can be a single solid piece or a laminated structure designed to minimize eddy current losses at high frequencies.

The core design is critical for ensuring that the transformer operates efficiently at its intended frequency range. High-frequency applications, such as those used in power supplies, benefit from ferrite cores, which exhibit low core losses at higher frequencies. For lower-frequency applications, a different core material, such as silicon steel, may be used for greater efficiency.

Windings and Layering

In a planar transformer, the primary and secondary windings are etched directly onto the PCB. These windings are typically made from copper or another conductive material, and their design follows a specific pattern that maximizes efficiency. The windings are often arranged in multiple layers to increase the surface area and reduce the resistance of the electrical path. The number of layers and the specific design of the windings are determined based on the required power capacity, efficiency, and voltage transformation ratio.

The windings are usually fabricated using photolithographic techniques, which enable precise control over the winding patterns and the spacing between them. This precision is essential for ensuring optimal transformer performance and minimizing losses due to factors such as parasitic capacitance or inductive coupling between windings.

How Does a Planar Transformer Work

The working principle of a planar transformer is based on the fundamental law of electromagnetic induction, which is the same as for traditional transformers. When an alternating current (AC) is applied to the primary winding, a magnetic field is generated around the winding. This magnetic field then induces a voltage in the secondary winding, which results in energy transfer between the two windings.

Magnetic Field Generation and Induction

The primary winding of a planar transformer is energized by an input AC signal, which generates a time-varying magnetic field around the winding. This magnetic field is confined within the transformer core, ensuring efficient energy transfer between the primary and secondary windings. The magnetic flux passes through the core and links with the secondary winding, inducing an electromotive force (EMF) that causes current to flow in the secondary circuit.

The voltage induced in the secondary winding is governed by Faraday’s law of induction, which states that the induced voltage is proportional to the rate of change of the magnetic flux through the winding. By adjusting the number of turns in the primary and secondary windings, the voltage transformation ratio can be controlled, allowing the transformer to step up or step down the voltage as required by the application.

Energy Transfer and Efficiency

In an ideal transformer, the power transferred from the primary winding to the secondary winding is equal, with minimal losses. However, in practice, losses do occur due to factors such as resistance in the windings (copper losses), core losses (hysteresis and eddy currents), and other parasitic effects. Planar transformers are designed to minimize these losses, especially at high frequencies, by using optimized core materials, efficient winding layouts, and low-resistance copper traces.

One of the key advantages of planar transformers is their improved efficiency at high switching frequencies. The flat winding structure minimizes the length of the electrical path, which reduces resistance and improves current distribution. Additionally, the tight coupling between the primary and secondary windings reduces the leakage inductance, leading to better energy transfer and higher efficiency.

Advantages of Planar Transformers

Planar transformers offer a range of benefits compared to traditional transformers. These advantages make them ideal for modern electronic applications that demand high performance, space efficiency, and low weight.

Compact Size and High Power Density

The most notable advantage of planar transformers is their compact size. Due to the flat winding design, planar transformers have a much lower profile compared to conventional transformers, making them ideal for use in applications where space is limited. This compactness allows for high power density, meaning that a planar transformer can provide more power in a smaller form factor. This is particularly beneficial in consumer electronics, where miniaturization is a key design goal.

Better Thermal Management

Planar transformers are also known for their superior thermal management. The flat winding structure allows for better heat dissipation because the windings are closer to the surface of the PCB. This results in a more efficient transfer of heat to the surrounding environment, reducing the risk of overheating and improving the transformer’s overall reliability. Additionally, the use of high-frequency switching in many planar transformers minimizes the heat generated by core losses, further enhancing their thermal performance.

Reduced Electromagnetic Interference (EMI)

Planar transformers tend to exhibit lower electromagnetic interference (EMI) compared to traditional transformers. This is because the windings are tightly coupled, which reduces the loop area and minimizes the amount of radiated electromagnetic energy. The reduced EMI is especially important in sensitive applications, such as telecommunications and medical devices, where noise and interference can impact the performance of the system.

Cost Efficiency and Scalability

While the initial design and manufacturing process of planar transformers may be more complex than traditional transformers, they offer cost advantages in the long run. The integration of the transformer into the PCB allows for a more streamlined manufacturing process, reducing the need for separate transformer components and simplifying assembly. Additionally, planar transformers can be easily scaled for different power levels and sizes, making them a versatile solution for a wide range of applications.

Applications of Planar Transformers

Planar transformers are widely used in various applications, particularly in areas where high efficiency, small size, and low weight are critical factors. Some of the key industries and use cases for planar transformers include:

Power Supplies

Planar transformers are commonly used in power supplies for electronic devices, including laptops, mobile phones, and industrial equipment. Their compact size and high efficiency make them ideal for converting AC to DC power in a variety of applications. Planar transformers are also used in switched-mode power supplies (SMPS), where their low-profile design and high-frequency performance are crucial for minimizing losses and reducing the size of the power supply unit.

Electric Vehicles

In the rapidly growing electric vehicle (EV) market, planar transformers are used for charging systems and inverters. EVs require efficient power conversion to manage the energy flow from the battery to the motor, and planar transformers provide a compact, high-efficiency solution. The low profile of planar transformers allows them to be integrated into the limited space available within electric vehicles, helping to reduce the overall size and weight of the vehicle’s power electronics.

Telecommunications

Planar transformers are also used in telecommunications systems, where their ability to handle high-frequency signals and minimize electromagnetic interference is highly valued. These transformers are used in signal transmission equipment, such as routers, amplifiers, and base stations, to ensure stable and efficient signal processing over long distances.

Renewable Energy Systems

With the rise of renewable energy sources such as solar and wind power, planar transformers are finding applications in power conversion systems for these energy sources. Inverters and power conditioning systems rely on efficient and compact transformers to convert the energy from solar panels or wind turbines into usable AC power. The small size and high efficiency of planar transformers make them an ideal solution for these systems, especially in space-constrained or portable setups.

Conclusion

Planar transformers represent a significant advancement in transformer technology, offering numerous advantages over traditional designs. Their compact size, high efficiency, and superior thermal management make them ideal for a wide range of modern applications, including power supplies, electric vehicles, telecommunications, and renewable energy systems. As the demand for smaller, more efficient electronic devices continues to grow, planar transformers will likely play an increasingly important role in powering the future of technology.

With their innovative design and performance benefits, planar transformers are poised to revolutionize the way electrical energy is transferred and managed in a variety of industries, paving the way for more compact, efficient, and reliable power systems in the years to come.