Flow measurement is a crucial aspect in various industrial, municipal, and commercial applications. Accurate measurement of fluid flow rates is essential for process control, system optimization, and safety monitoring. Among the diverse range of flow measurement instruments available, ultrasonic flowmeters have gained significant traction due to their non-intrusive nature and versatility. Clamp-on ultrasonic flowmeters, a specialized subset, offer unique advantages that address common challenges faced by traditional flow measurement technologies.

What Is a Clamp-On Ultrasonic Flowmeter?

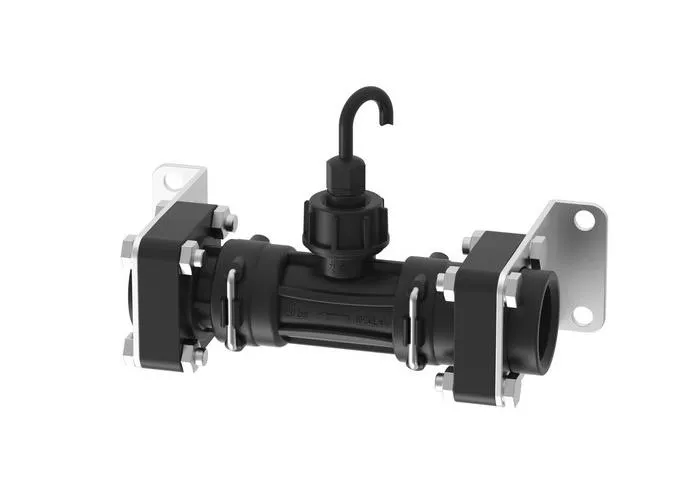

A clamp-on ultrasonic flowmeter is a device that measures the flow velocity of liquids inside a pipe without requiring any modification or penetration of the pipe itself. Unlike inline flowmeters that necessitate cutting into the pipeline, clamp-on ultrasonic flowmeters attach externally by clamping transducers onto the pipe’s outer surface. This non-invasive approach allows for quick installation, minimal disruption, and zero risk of leakage or contamination.

Fundamental Principles Behind Clamp-On Ultrasonic Flowmeters

Ultrasonic Flow Measurement Concepts

Ultrasonic flowmeters operate by transmitting high-frequency sound waves through a fluid and measuring the changes in the wave’s propagation caused by fluid movement. The two primary methods employed are the transit-time and Doppler techniques, both leveraging the interaction of sound waves with flowing media to deduce flow velocity.

Transit-Time Method

The transit-time principle involves two ultrasonic transducers positioned on opposite sides of the pipe. One transducer sends an ultrasonic pulse downstream (with the flow), while the other sends a pulse upstream (against the flow). Because the fluid’s velocity affects the speed of sound traveling in each direction, the difference in transit times between upstream and downstream pulses is directly proportional to the flow velocity. By precisely measuring these times, the flowmeter calculates the volumetric flow rate.

Doppler Method

The Doppler method applies when the fluid contains particles or bubbles that reflect ultrasonic signals. A single transducer emits sound waves into the flow, which reflect off moving particles. The reflected wave’s frequency shifts in proportion to the flow velocity, a phenomenon known as the Doppler effect. The flowmeter analyzes this frequency shift to determine flow velocity.

Construction and Design of Clamp-On Ultrasonic Flowmeters

Transducer Configuration and Types

Clamp-on ultrasonic flowmeters rely on transducers that convert electrical signals into ultrasonic pulses and vice versa. The transducers are typically piezoelectric crystals housed in waterproof, rugged casings designed for secure clamping to pipes of various materials and diameters. Some designs allow for dual transducers operating in a differential mode to enhance accuracy.

Clamp Mechanism and Pipe Compatibility

The clamp assembly is engineered to maintain firm and stable contact between the transducer and pipe wall, ensuring consistent signal transmission. These clamps accommodate pipes made from metal (steel, stainless steel, copper), plastic (PVC, HDPE), and composite materials. However, accurate flow measurement requires proper acoustic coupling, often achieved using specialized gels or pads to eliminate air gaps.

Electronics and Signal Processing Units

The core electronics unit processes signals received from the transducers, executing time measurements, frequency analysis, and flow calculations. Advanced algorithms filter noise, compensate for temperature and pipe size variations, and provide outputs compatible with industrial communication protocols like 4-20 mA, Modbus, or HART.

Operational Workflow of Clamp-On Ultrasonic Flowmeters

Installation Procedure

Installation begins by selecting an appropriate straight pipe section free from bends, valves, or fittings that can disturb flow profiles. The clamp-on transducers are affixed on opposite sides of the pipe, aligned accurately according to manufacturer guidelines. A coupling agent is applied to ensure optimal acoustic transmission. The electronics unit is then configured to the pipe’s dimensions and fluid characteristics.

Measurement Process

Once installed and calibrated, the flowmeter emits ultrasonic pulses through the pipe wall into the fluid. By measuring either the transit time difference or the Doppler frequency shift of the signals, the device computes the flow velocity. This velocity, combined with the pipe’s cross-sectional area, provides the volumetric flow rate.

Data Output and Integration

The flowmeter continuously monitors the flow and outputs real-time data for display, logging, or process control. Many models offer diagnostic features that alert operators to installation issues, signal degradation, or changes in fluid composition. Integration with SCADA or DCS systems is common in industrial environments.

Advantages of Clamp-On Ultrasonic Flowmeters

Non-Invasive and No Process Interruption

Because clamp-on ultrasonic flowmeters do not require cutting or intruding into the pipeline, they eliminate the risk of leaks, pressure loss, or contamination. This makes them ideal for critical processes and hazardous fluids where pipeline integrity is paramount.

Easy Installation and Maintenance

The external clamping design allows for rapid deployment without specialized tools or shutdowns, significantly reducing downtime and labor costs. Maintenance is minimal since there is no direct contact with the fluid, thus no wear or fouling of sensing elements.

Versatility Across Pipe Materials and Sizes

Clamp-on flowmeters are suitable for a broad spectrum of pipe materials and sizes, accommodating small to large diameters and various fluid types. This adaptability simplifies inventory and application scope.

High Accuracy and Repeatability

Modern clamp-on ultrasonic flowmeters incorporate sophisticated signal processing and calibration routines that ensure precise flow measurements under diverse operating conditions. Accuracy typically ranges between ±1% and ±2% of reading.

Limitations and Considerations

Dependence on Pipe Material and Condition

Acoustic transmission efficiency varies with pipe wall material, thickness, and surface condition. Corroded, insulated, or lined pipes may attenuate the ultrasonic signals, reducing measurement reliability.

Requirement for Straight Pipe Runs

Disturbed or turbulent flow near bends, valves, or fittings can introduce errors. Manufacturers usually specify minimum upstream and downstream straight pipe lengths to ensure fully developed flow profiles.

Fluid Characteristics

The transit-time method assumes a clean fluid without entrained particles or bubbles. For fluids with significant suspended solids or gas bubbles, the Doppler method may be preferred, but it too has limitations regarding flow regime and particle size.

Temperature and Pressure Constraints

Extreme temperatures or pressures may affect transducer performance and acoustic coupling, necessitating specialized equipment or protective measures.

Applications of Clamp-On Ultrasonic Flowmeters

Water and Wastewater Management

Municipal water utilities employ clamp-on flowmeters for monitoring distribution networks, detecting leaks, and managing consumption without interrupting service.

Chemical and Petrochemical Industries

Non-intrusive measurement is crucial for corrosive, toxic, or high-purity fluids, where clamp-on devices minimize contamination risk and maintenance downtime.

HVAC and Energy Monitoring

Building management systems utilize these flowmeters to optimize heating and cooling loops, improving energy efficiency and occupant comfort.

Food and Beverage Processing

Sanitary applications benefit from non-contact measurement, maintaining hygiene standards and allowing quick reconfiguration of process lines.

Conclusion

Clamp-on ultrasonic flowmeters represent a sophisticated, non-intrusive solution for accurate fluid flow measurement across a wide range of industries. Their ability to clamp externally to pipes without disrupting flow or compromising pipeline integrity makes them invaluable where reliability, safety, and ease of maintenance are priorities. By understanding their operating principles, installation requirements, and limitations, engineers and operators can effectively leverage clamp-on ultrasonic flowmeters to optimize process control and resource management. As technology evolves, these devices will continue to offer greater precision, connectivity, and adaptability in fluid measurement applications.