Dry type distribution transformers are an essential component of modern electrical power systems. Unlike their oil-immersed counterparts, dry type transformers use air as the cooling medium and are characterized by their safety, environmental compatibility, and versatility in installation environments. These transformers are primarily used in commercial, industrial, and institutional facilities where fire hazards, environmental concerns, or space constraints limit the use of oil-filled transformers.

This article explores the fundamental design, working principles, types, benefits, and applications of dry type distribution transformers. It also delves into their advantages over oil-immersed models and addresses common misconceptions and technical considerations related to their operation.

What is a Transformer?

A transformer is an electromagnetic device that transfers electrical energy between two or more circuits through electromagnetic induction. It operates on the principle of Faraday’s Law of Electromagnetic Induction, which states that a change in magnetic flux in a coil induces an electromotive force (EMF) in a neighboring coil.

Transformers are primarily used to increase (step-up) or decrease (step-down) voltage levels in power distribution networks, thereby facilitating efficient power transmission over long distances and ensuring appropriate voltage levels for end-use applications.

What Defines a Dry Type Distribution Transformer?

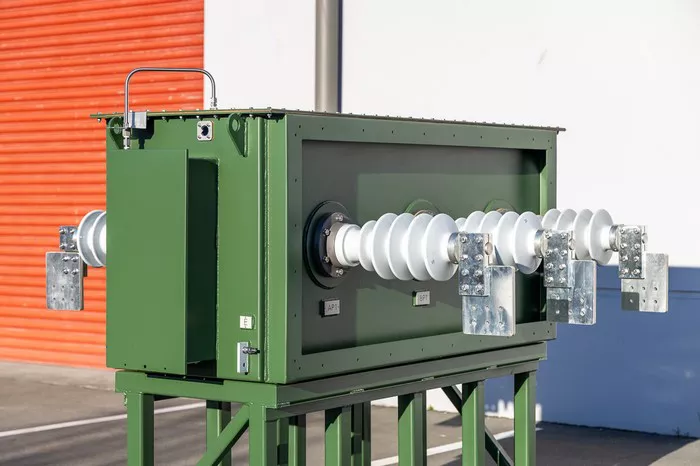

A dry type distribution transformer, as the name implies, does not contain any liquid coolant like mineral oil or synthetic esters. Instead, its core and windings are cooled by natural air or forced air circulation. The insulating material used in these transformers is solid and non-flammable, often made of epoxy resin, polyester resin, or other thermosetting resins.

These transformers are typically used in voltages below 36 kV and are ideal for indoor installations due to their fire-resistant and environmentally friendly properties.

Construction of Dry Type Distribution Transformers

Dry type transformers share several design features with traditional oil-filled transformers but incorporate distinct construction elements that cater to their unique cooling and insulation requirements. The main components include:

1. Core

The magnetic core is made from laminated silicon steel sheets to minimize eddy current losses and enhance magnetic efficiency. The core is designed to carry the magnetic flux generated by the primary winding.

2. Windings

The windings are typically made of copper or aluminum conductors and are insulated with high-temperature materials. Two major winding insulation technologies are used:

- VPI (Vacuum Pressure Impregnated): Windings are impregnated with polyester or epoxy varnish under vacuum and pressure conditions to ensure uniform insulation.

- Cast Resin: The windings are encased in epoxy resin, providing high mechanical strength and environmental protection.

3. Enclosure

Dry type transformers are usually enclosed in a ventilated or non-ventilated enclosure made of steel or aluminum to protect against dust, moisture, and mechanical damage.

4. Cooling System

Air is the primary cooling medium. Depending on the size and application, cooling can be:

- AN (Air Natural): Natural convection cooling.

- AF (Air Forced): Fans are used to force air across the windings to improve cooling efficiency.

How Dry Type Transformers Work

The working principle of dry type transformers is similar to that of conventional transformers. When an alternating current (AC) flows through the primary winding, it generates a magnetic flux in the core. This flux links to the secondary winding through the core, inducing a voltage according to the turns ratio between the primary and secondary coils.

Since these transformers do not use oil, heat generated in the windings and core is dissipated directly to the surrounding air. Efficient thermal management and insulation design are critical for maintaining performance and longevity.

Types of Dry Type Distribution Transformers

There are several classifications of dry type transformers based on insulation technology and application:

1. Cast Resin Transformers (CRT)

These are the most common dry type transformers. The windings are cast in epoxy resin, which provides excellent protection against moisture, dust, and chemical contaminants. CRTs are suitable for environments with high humidity or pollution levels.

2. Vacuum Pressure Impregnated (VPI) Transformers

In VPI transformers, windings are vacuum impregnated with varnish and cured in an oven. Though less robust than CRTs in harsh environments, VPI transformers offer good mechanical strength and lower initial cost.

3. Open Wound Transformers

These use standard winding methods without resin or varnish impregnation and are typically used in clean and controlled environments such as laboratories.

Applications of Dry Type Distribution Transformers

Dry type distribution transformers are used across a wide array of applications due to their safety and adaptability:

- Commercial buildings (malls, office complexes)

- Hospitals and healthcare facilities

- Schools and universities

- Data centers

- Subways and airports

- Renewable energy installations (solar and wind farms)

- Heavy industries (mining, cement, manufacturing)

Advantages of Dry Type Distribution Transformers

1. Fire Safety

Without flammable liquids, dry type transformers significantly reduce fire hazards. This makes them ideal for indoor and confined space installations where safety is paramount.

2. Environmental Friendliness

They eliminate the risk of oil leaks and soil contamination, making them a preferred choice in eco-sensitive zones.

3. Low Maintenance

With no need to check oil levels or test for oil quality, maintenance is simpler and less frequent. The use of solid insulation also reduces degradation over time.

4. Cost Efficiency in the Long Term

Though the initial cost may be higher, the reduced risk of fire, lower maintenance expenses, and longer service life can result in cost savings over the lifespan of the transformer.

5. Compact and Versatile Design

Dry type transformers can be installed closer to the load center, reducing cable costs and voltage drops. They are also available in a variety of enclosures to suit different environmental conditions.

Limitations of Dry Type Distribution Transformers

1. Lower Power Rating

Dry type transformers are typically not used for very high power applications due to limitations in cooling capacity and insulation stress.

2. Noise Levels

The absence of liquid damping can make dry type transformers noisier than their oil-filled counterparts, although this can be mitigated with soundproof enclosures.

3. Higher Initial Cost

Advanced insulation materials and manufacturing processes contribute to a higher upfront cost compared to oil-immersed units.

Maintenance and Testing Practices

Although low maintenance, dry type transformers still require periodic inspections to ensure optimal performance. Key practices include:

- Visual inspection for dust, corrosion, or physical damage

- Cleaning of windings and enclosures using dry compressed air

- Thermal scanning to detect hot spots

- Insulation resistance testing using a megohmmeter

- Tightening of electrical connections

Industry Standards and Compliance

Dry type distribution transformers must comply with standards set by national and international bodies. Some key standards include:

- IEEE C57.12.01 – General requirements for dry-type distribution transformers

- IEC 60076 – Power transformers (Part 11 for dry type)

- ANSI C57 – American National Standards Institute regulations

- NEMA ST20 – National Electrical Manufacturers Association

Recent Innovations in Dry Type Transformer Technology

Recent advancements are improving the performance, reliability, and sustainability of dry type transformers:

- Smart Monitoring Systems: IoT-based sensors for real-time temperature, humidity, and load monitoring.

- Advanced Cooling Techniques: Hybrid air and water cooling systems for better thermal management.

- High Efficiency Designs: Use of amorphous metal cores to reduce no-load losses.

- Recyclable Materials: Eco-friendly resins and materials to promote sustainability.

Conclusion

Dry type distribution transformers are a reliable and safe alternative to traditional oil-immersed units, particularly suited for environments where fire safety and environmental considerations are paramount. Their air-cooled design, solid insulation, and low maintenance requirements make them an increasingly popular choice across industries.

With advancements in materials, monitoring systems, and cooling technologies, dry type transformers are poised to play a vital role in the future of power distribution. Their adaptability, safety profile, and environmental benefits make them a cornerstone of modern electrical infrastructure, especially as the demand for cleaner, more sustainable energy systems continues to grow.

Whether in high-rise buildings, renewable energy sites, or sensitive public facilities, dry type distribution transformers offer a robust, efficient, and responsible solution to meet contemporary energy needs.