Magnetic sensors are devices designed to detect and measure magnetic fields, including their strength, direction, or changes over time. These sensors play an essential role in modern technology, spanning diverse industries such as automotive, aerospace, consumer electronics, industrial automation, and medical applications. By converting magnetic information into electrical signals, magnetic sensors enable machines and systems to interact intelligently with their environment.

Historical Context

The principle of detecting magnetic fields has been known for centuries, with early compasses serving as rudimentary magnetic sensors guiding navigation. The evolution from mechanical compasses to solid-state magnetic sensors parallels advancements in materials science and semiconductor technology, culminating in highly sensitive, miniaturized sensors used today.

Types of Magnetic Sensors

Hall Effect Sensors

Hall Effect sensors operate on the principle discovered by Edwin Hall in 1879. When a conductor or semiconductor carrying current is exposed to a magnetic field perpendicular to the current, a voltage—known as the Hall voltage—is generated across the conductor. This voltage is proportional to the magnetic field strength, making Hall sensors ideal for measuring magnetic flux density. They are widely used in position sensing, speed detection, and current sensing.

Magnetoresistive Sensors

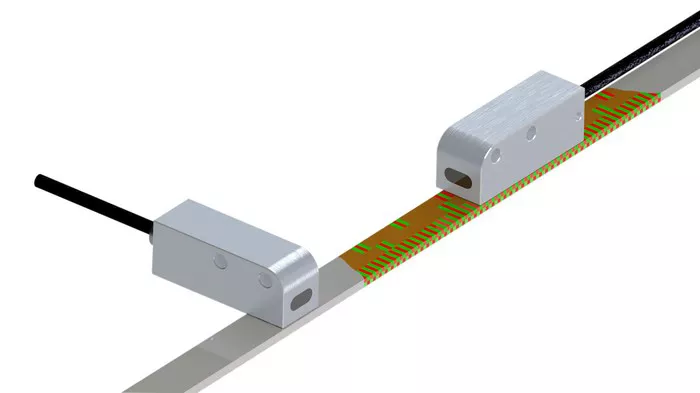

Magnetoresistive (MR) sensors exploit changes in electrical resistance when subjected to a magnetic field. There are several variants, including Anisotropic Magnetoresistance (AMR), Giant Magnetoresistance (GMR), and Tunnel Magnetoresistance (TMR). GMR and TMR sensors offer higher sensitivity than traditional Hall sensors, making them useful in applications requiring precise magnetic field detection, such as hard disk read heads and magnetic encoders.

Fluxgate Sensors

Fluxgate sensors are highly sensitive devices that measure the intensity and direction of magnetic fields. They consist of ferromagnetic cores wrapped with excitation and sensing coils. By driving the core into magnetic saturation and analyzing the output from the sensing coil, fluxgate sensors can detect very weak magnetic fields, including the Earth’s magnetic field, and are often used in navigation and geophysical research.

Inductive and Search Coil Sensors

Inductive sensors detect changes in magnetic fields by measuring induced voltages in coils. Search coil sensors operate on the principle of Faraday’s law of induction and are typically used to measure time-varying magnetic fields, especially in power systems and electromagnetic compatibility testing.

Magnetoimpedance Sensors

These sensors use the magnetoimpedance effect, where the electrical impedance of a ferromagnetic material changes with the applied magnetic field. They are recognized for their high sensitivity and low power consumption, making them suitable for biomedical and industrial sensing.

How Do Magnetic Sensors Work

Interaction of Magnetic Fields and Materials

Magnetic sensors detect magnetic fields by exploiting the interaction between magnetic flux and the sensor’s active material. When a magnetic field interacts with certain materials or semiconductor structures, measurable physical effects occur—such as voltage generation, resistance changes, or inductive voltage induction—that can be converted into electrical signals.

Hall Effect in Detail

In Hall Effect sensors, a current is applied through a thin strip of semiconductor or metal. When an external magnetic field perpendicular to this current passes through the strip, it exerts a Lorentz force on the moving charge carriers (electrons or holes), deflecting them to one side. This deflection causes a potential difference (Hall voltage) perpendicular to both the current and the magnetic field, which is proportional to the field strength. The sensor electronics then amplify and process this voltage to derive meaningful measurements.

Magnetoresistive Effects Explained

Magnetoresistive sensors rely on changes in electrical resistance influenced by magnetic fields. In AMR sensors, resistance varies with the angle between the direction of electric current and the magnetization of the material. GMR and TMR sensors achieve larger resistance changes due to quantum mechanical effects in multilayer thin films or tunnel junctions. When an external magnetic field alters the magnetization alignment between layers, resistance shifts significantly, allowing precise detection of magnetic fields.

Fluxgate Sensor Operation

Fluxgate sensors function by periodically driving a ferromagnetic core into saturation using an excitation coil energized with an alternating current. In the absence of an external magnetic field, the output of the sensing coil is symmetrical and cancels out. When an external magnetic field is present, the core saturates asymmetrically, inducing a measurable voltage in the sensing coil proportional to the field’s magnitude and direction.

Inductive Sensing Mechanics

Inductive sensors detect magnetic field variations based on Faraday’s law of electromagnetic induction. A coil exposed to a changing magnetic field experiences a change in magnetic flux, which induces an electromotive force (EMF) or voltage in the coil. The induced voltage is proportional to the rate of change of the magnetic field, enabling detection of alternating or transient magnetic fields.

Applications of Magnetic Sensors

Automotive Industry

Magnetic sensors are integral to modern vehicles, used in applications such as wheel speed detection for anti-lock braking systems (ABS), crankshaft and camshaft position sensing for engine management, and electronic power steering. Their contactless, wear-free operation enhances reliability and durability under harsh automotive conditions.

Consumer Electronics

Smartphones, tablets, and wearable devices frequently incorporate magnetic sensors for compass functionality, orientation detection, and proximity sensing. Magnetic sensors also enable features like magnetic stylus detection and smart cover recognition in tablets and laptops.

Industrial Automation and Robotics

In industrial environments, magnetic sensors facilitate precise position and speed measurement in motors, conveyor belts, and robotic arms. Their ability to function in dirty or harsh environments without physical contact makes them indispensable for automation and control systems.

Medical Devices

Magnetic sensors are employed in medical instruments for applications such as magnetic resonance imaging (MRI), magnetocardiography, and the tracking of surgical instruments. Their sensitivity and ability to detect subtle magnetic signals are critical in these contexts.

Navigation and Geophysics

Magnetometers, a category of magnetic sensors, are used in navigation systems for detecting Earth’s magnetic field, aiding in direction finding and location services. In geophysics, magnetic sensors help in mineral exploration, earthquake prediction research, and archaeological investigations.

Advantages and Limitations of Magnetic Sensors

Advantages

- Contactless Sensing: Magnetic sensors operate without mechanical contact, reducing wear and maintenance.

- High Reliability and Durability: They function reliably in harsh environments, including dust, dirt, oil, and moisture.

- Wide Measurement Range: Capable of detecting both weak and strong magnetic fields.

- Fast Response Time: Suitable for dynamic measurement of position, speed, and current.

- Miniaturization: Easily integrated into compact electronic devices.

Limitations

- Susceptibility to External Interference: Nearby magnetic sources can influence measurements.

- Temperature Sensitivity: Sensor accuracy can degrade with temperature fluctuations, requiring compensation.

- Calibration Requirements: Many sensors need periodic calibration to maintain accuracy.

- Limited Range for Some Types: Some sensors only measure within a limited magnetic field strength range.

Conclusion

Magnetic sensors are indispensable components in today’s technology landscape, bridging the physical magnetic world with electronic systems through various sensing principles such as the Hall Effect, magnetoresistance, and inductive coupling. Their versatility, reliability, and sensitivity enable a broad spectrum of applications, from automotive safety systems to cutting-edge medical devices. Continued advancements in materials science and integration with digital technologies promise to expand their capabilities even further, reinforcing the critical role magnetic sensors will play in future innovations.

FAQs

What is the main difference between Hall Effect and Magnetoresistive sensors?

Hall Effect sensors detect magnetic fields by generating a voltage perpendicular to current flow when exposed to a magnetic field, whereas Magnetoresistive sensors detect changes in electrical resistance due to magnetic field-induced alignment changes in their material structure. Magnetoresistive sensors typically offer higher sensitivity than Hall Effect sensors.

Can magnetic sensors detect both static and dynamic magnetic fields?

Yes, some magnetic sensors such as Hall Effect and magnetoresistive sensors can detect static (DC) magnetic fields, while others like inductive coils and fluxgate sensors are better suited for detecting dynamic (AC) magnetic fields.

How do temperature changes affect magnetic sensor accuracy?

Temperature variations can alter the electrical properties of sensor materials and influence magnetic characteristics, causing measurement drift or errors. Many magnetic sensors include temperature compensation mechanisms to maintain accuracy across varying environments.

Are magnetic sensors affected by nearby metals or magnetic materials?

Yes, ferromagnetic materials and nearby magnetic sources can distort the magnetic field being measured, potentially causing inaccurate readings. Proper sensor placement and shielding are often necessary to minimize interference.

How do fluxgate sensors compare to other magnetic sensors in sensitivity?

Fluxgate sensors are among the most sensitive magnetic sensors, capable of detecting very weak magnetic fields, such as Earth’s geomagnetic field, which many other sensor types cannot measure accurately without amplification.

Can magnetic sensors be used for current measurement?

Yes, Hall Effect sensors and some magnetoresistive sensors are widely used to measure electric current by detecting the magnetic field generated around current-carrying conductors.

Is it possible to use magnetic sensors in harsh environmental conditions?

Absolutely. Magnetic sensors are well-suited for harsh environments because they are contactless, solid-state, and can be packaged to resist dust, moisture, and vibrations.