Fluxgate sensors are a specialized type of magnetic sensor widely used in fields that require precise measurement of magnetic fields. These sensors offer high sensitivity and accuracy, enabling their application in geophysics, aerospace, navigation systems, and industrial instrumentation. Understanding what fluxgate sensors are and how they operate is essential for engineers, researchers, and technicians who work with magnetic field detection and related technologies.

What Are Fluxgate Sensors

At their core, fluxgate sensors measure the intensity and direction of magnetic fields. Unlike simple magnetometers, fluxgate sensors utilize the magnetic saturation properties of ferromagnetic materials to detect minute changes in magnetic flux. This fundamental principle allows these sensors to detect very low-level magnetic fields, even those weaker than the Earth’s geomagnetic field.

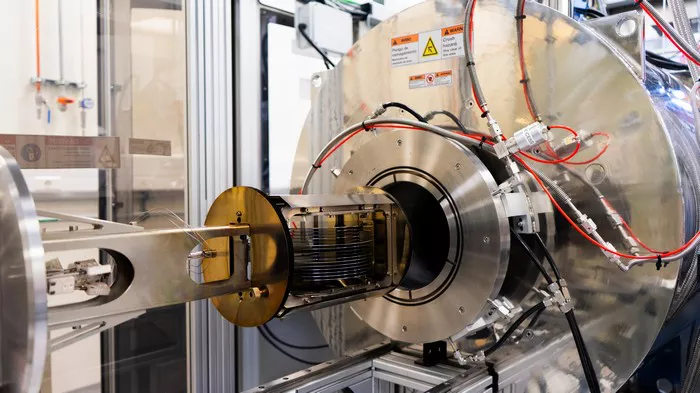

Fluxgate sensors consist mainly of a ferromagnetic core wrapped by two coils: a drive coil and a sense coil. The drive coil is energized with an alternating current, magnetizing the core alternately in opposite directions. The external magnetic field to be measured influences the magnetic saturation of the core, which affects the voltage induced in the sense coil. By analyzing this induced voltage, the sensor can determine the magnitude and polarity of the surrounding magnetic field.

How Fluxgate Sensors Work

The operating principle of fluxgate sensors is grounded in magnetic saturation and the nonlinear magnetization of ferromagnetic cores. Here’s a detailed step-by-step explanation of how fluxgate sensors work:

1. Excitation of the Magnetic Core

The fluxgate sensor’s core is driven by an alternating current flowing through the drive coil. This alternating current cyclically saturates the ferromagnetic core first in one direction and then in the opposite direction. The drive coil thus produces a magnetizing field that pushes the core material to its magnetic limits, where its permeability drastically changes.

2. Influence of the External Magnetic Field

The presence of an external magnetic field biases the magnetic state of the core. Because the external field adds to or subtracts from the drive coil’s magnetizing field, it causes an asymmetry in the magnetic saturation cycle. This asymmetry alters the pattern of magnetic flux in the core during each AC cycle.

3. Detection via Sense Coil

The sense coil, wound around the same core, detects changes in magnetic flux. When the core saturates symmetrically (without an external magnetic field), the voltage induced in the sense coil is ideally zero at certain points in the cycle. However, when the core saturation is shifted due to an external field, the induced voltage contains harmonics—primarily at twice the drive frequency. These harmonic voltages are extracted through signal processing circuits.

4. Signal Processing and Output

The signal processing electronics filter the sense coil output to isolate the second harmonic component, which is proportional to the external magnetic field intensity. The polarity of the external field determines the phase of the harmonic signal. This output voltage is then converted to a digital or analog signal representing the magnetic field’s strength and direction.

Types of Fluxgate Sensors

There are several types of fluxgate sensors tailored for different applications. The most common configurations include:

Core Shape and Design Variations

- Rod Core Fluxgate: Utilizes a straight ferromagnetic rod as the core, simple in design but effective for many applications.

- Ring Core Fluxgate: Employs a toroidal (ring-shaped) core which reduces magnetic interference and increases sensitivity.

- Planar Fluxgate: Designed using thin-film technology for compactness and integration into microelectromechanical systems (MEMS).

Single-Axis and Multi-Axis Fluxgate Sensors

Fluxgate sensors can be designed to measure magnetic fields along a single axis or multiple axes. Multi-axis sensors are particularly valuable in applications like navigation and geomagnetic surveys where the three-dimensional magnetic field vector is required.

Applications of Fluxgate Sensors

Thanks to their precision and reliability, fluxgate sensors find use in a variety of fields:

- Navigation Systems: Fluxgate sensors serve as electronic compasses in aircraft, marine vessels, and autonomous vehicles, providing accurate heading information.

- Geophysical Exploration: Used in mineral exploration and archaeology to detect magnetic anomalies in the Earth’s crust.

- Industrial Instrumentation: Fluxgate sensors monitor magnetic fields in electrical machines and transformers, contributing to diagnostics and condition monitoring.

- Space Research: Satellites and space probes use fluxgate sensors for mapping planetary magnetic fields and studying solar wind interactions.

- Military and Defense: Used in missile guidance, submarine detection, and other sensitive magnetic field measurements.

Fluxgate sensors also integrate with other sensor technologies. For example, they are often paired with instrumentation systems to enhance precision measurement capabilities. This integration allows for comprehensive environmental monitoring where magnetic data is critical.

Advantages and Limitations

Advantages

- High Sensitivity: Capable of detecting very weak magnetic fields down to fractions of a nanotesla.

- Stable and Reliable: Low drift over time and resistance to temperature variations.

- Directional Measurement: Ability to measure both the magnitude and direction of magnetic fields.

- Non-contact Sensing: Can measure magnetic fields without physically touching the source.

Limitations

- Size and Complexity: Traditional fluxgate sensors tend to be bulkier compared to some modern magnetic sensors like Hall-effect sensors.

- Power Consumption: Requires continuous excitation current, which may not be ideal for low-power applications.

- Signal Processing Requirements: The output requires sophisticated electronics to extract meaningful data, increasing system complexity.

Technological Developments and Innovations

Recent advances have pushed fluxgate sensor technology into new realms. The miniaturization of fluxgate sensors through MEMS technology has led to smaller, more robust devices with reduced power consumption. Integration with digital signal processors allows for enhanced noise filtering and calibration, improving overall sensor performance.

In addition, combining fluxgate sensors with other sensor modalities such as vibration sensors or fiber optic sensors enables multi-parameter monitoring platforms. This synergistic approach expands the utility of fluxgate sensors beyond traditional applications.

Installation and Calibration Considerations

For accurate measurement, proper installation and calibration of fluxgate sensors are critical. The sensor must be oriented correctly relative to the expected magnetic field direction. Calibration often involves exposing the sensor to known magnetic fields and adjusting the output to match reference values.

Environmental factors such as nearby ferromagnetic materials, electrical noise, and temperature variations must be minimized or compensated for to avoid measurement errors. Regular recalibration may be necessary to maintain accuracy over the sensor’s operational lifetime.

Conclusion

Fluxgate sensors represent a mature yet continually evolving technology that excels in measuring magnetic fields with high sensitivity and directional accuracy. Their operation is based on the nonlinear magnetic saturation of ferromagnetic cores influenced by external fields, translated into usable electrical signals through sophisticated signal processing. The applications of fluxgate sensors span from navigation and geophysics to industrial instrumentation and space research.

Understanding the principles, advantages, and limitations of fluxgate sensors is essential for engineers and scientists designing magnetic measurement systems. Coupling fluxgate sensors with other technologies like level sensors or integrating them into multi-sensor platforms can further enhance their utility across diverse applications.

FAQs

What is the main advantage of fluxgate sensors compared to other magnetic sensors?

Fluxgate sensors offer superior sensitivity and accuracy in detecting very low magnetic fields, which many other sensors, such as Hall-effect sensors, cannot achieve as effectively.

Can fluxgate sensors measure magnetic fields in three dimensions?

Yes, multi-axis fluxgate sensors are designed to measure magnetic fields along three orthogonal directions, providing complete vector information about the magnetic environment.

Are fluxgate sensors affected by temperature changes?

While fluxgate sensors are generally stable, temperature variations can cause some drift. High-quality sensors include temperature compensation features or require calibration to maintain accuracy.

What kind of applications benefit most from fluxgate sensors?

Applications requiring precise magnetic field measurement such as navigation, geophysical surveys, aerospace instrumentation, and industrial diagnostics benefit greatly from fluxgate sensors.

How do fluxgate sensors compare to infrared sensors?

Fluxgate sensors measure magnetic fields, while infrared sensors detect thermal radiation. They serve very different functions, though both can be part of complex instrumentation systems.