A single-engine, as the name suggests, refers to an engine configuration that powers a vehicle or machinery with a single power unit. These engines are commonly found in various types of applications such as aviation, automobiles, and industrial machines. The design and mechanics behind single-engine systems are varied, depending on their purpose. A single-engine is often designed to be lightweight, efficient, and reliable for specific operational needs, making it a crucial component in countless engineering systems around the world.

In this article, we explore what a single-engine is, its working principles, and the key features that make it indispensable across different domains, from aviation to automotive engineering. Additionally, we will delve into different engine types that fall under the single-engine category and how they function in their respective fields.

What Is a Single-Engine

At the most fundamental level, a single-engine refers to an internal combustion engine that uses a single unit to generate power to drive a machine or vehicle. This type of engine is integral to its application, typically by converting chemical energy stored in fuel into mechanical energy. Single-engine systems are primarily used in machines that require a simple, efficient power source, where the need for multiple engines would only add unnecessary weight, complexity, and cost.

Key Components of a Single-Engine

Just like other engines, single-engine systems comprise a set of critical components that work in harmony to generate power. These include:

- Cylinder: The main chamber where fuel combustion occurs. It plays a vital role in the overall performance of the engine.

- Piston: The piston moves inside the cylinder, transferring the force from the combustion process to mechanical energy.

- Crankshaft: This component converts the piston’s linear motion into rotational energy.

- Fuel system: This includes the fuel injectors, carburetors, or fuel pumps that provide the engine with fuel for combustion.

- Ignition system: Responsible for igniting the fuel-air mixture in the engine’s cylinder.

Types of Single-Engine Systems

Single-engine systems can be categorized into different types based on their configuration, cycle, and fuel type. The common types of single-engine configurations are:

- Inline engines: These are engines where the cylinders are arranged in a straight line. Inline-4 engines are a common example used in compact vehicles. The inline-4 engine is one of the most popular configurations due to its simplicity and fuel efficiency.

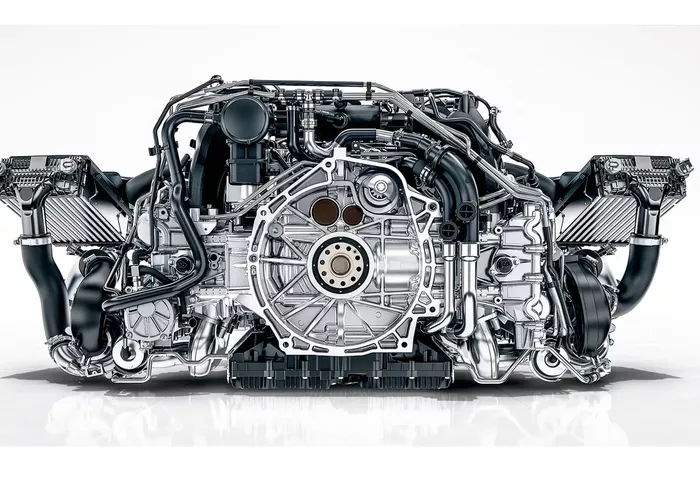

- Flat engines: These engines have cylinders arranged in a horizontally opposed configuration. A popular example is the flat-six engine found in vehicles like Porsche sports cars. Flat engines offer smoother operation and a lower center of gravity, which enhances vehicle stability.

- Rotary engines: Known for their unique design, rotary engines use a rotary motion instead of reciprocating pistons. Although not widely used, they are known for their smoothness and higher power output relative to their size. Rotary engines are commonly found in some older Mazda vehicles, like the RX-7.

How Does a Single-Engine Work?

The basic operating principle behind a single-engine is the internal combustion process. In this process, fuel and air are mixed together, and the resulting mixture is ignited to create a controlled explosion. This explosion generates high-pressure gases that push a piston within the cylinder. The piston’s movement then turns the crankshaft, which ultimately drives the vehicle’s wheels or another component of the machine.

The Four-Stroke Cycle

One of the most commonly used internal combustion cycles in single-engine systems is the four-stroke cycle. The four-stroke engine operates in four distinct phases:

- Intake stroke: The intake valve opens, and the piston moves down, drawing in a mixture of fuel and air.

- Compression stroke: The intake valve closes, and the piston moves up, compressing the fuel-air mixture.

- Power stroke: The spark plug ignites the compressed fuel-air mixture, causing an explosion. The resulting force pushes the piston down, which in turn rotates the crankshaft.

- Exhaust stroke: The exhaust valve opens, and the piston moves up again, expelling the exhaust gases produced during combustion.

In the case of 4-cycle engines, this cycle is repeated continuously, ensuring a smooth, efficient power output. The efficiency of this system makes it ideal for various applications, from automobiles to lawn mowers.

The Two-Stroke Cycle

Another type of single-engine system uses a two-stroke cycle. This system is different from the four-stroke cycle because it completes the entire combustion process in just two strokes of the piston. While two-stroke engines are generally less fuel-efficient than their four-stroke counterparts, they offer higher power output relative to their size, making them suitable for small machinery, motorcycles, and chainsaws.

In a two-stroke engine, both the intake and exhaust processes occur as the piston moves up and down once, combining both the compression and exhaust stages into a single movement. This compact system allows for a simpler design but typically results in greater emissions and less fuel efficiency compared to a four-stroke engine.

Applications of Single-Engine Systems

Aviation: The Backbone of Light Aircraft

In aviation, the single-engine is a critical element in light aircraft design. Many small airplanes are powered by single-engine systems, especially those designed for training, recreational flying, and short regional flights. These engines are favored for their reliability, ease of maintenance, and lower cost compared to multi-engine aircraft.

Single-engine aircraft typically use either a four-stroke or a two-stroke engine, depending on the aircraft’s specific needs. For example, popular small planes such as the Cessna 172 are equipped with four-stroke gasoline engines, offering reliable power while keeping maintenance and operational costs manageable.

Automobiles: Efficiency and Compact Design

In the automotive industry, single-engine systems are widely used in vehicles such as compact cars, motorcycles, and other light vehicles. The single-engine system, especially when configured as an inline-4, is a popular choice for these vehicles due to its compact size, simplicity, and fuel efficiency. Engines such as the inline-4 engine are known for their ability to balance performance with economy, making them a common feature in everyday cars.

Small Machinery: Power for Everyday Tools

Single-engine systems are also commonly used in small machinery such as lawnmowers, chainsaws, and generators. These engines are designed to deliver consistent and reliable power in applications that require portability and ease of use. In particular, two-stroke engines are often favored in these tools due to their lightweight design and the ability to generate high power output relative to their size.

Advantages and Limitations of Single-Engine Systems

Advantages of Single-Engine Systems

Single-engine systems are widely favored due to their various advantages, including:

- Cost-Effectiveness: Single engines are generally cheaper to manufacture and maintain than multi-engine systems. This makes them a popular choice for cost-conscious applications.

- Simplicity: The design and operation of single-engine systems are simpler than their multi-engine counterparts, reducing the complexity of maintenance and repair.

- Fuel Efficiency: Single-engine systems, especially four-stroke engines, are typically more fuel-efficient, making them an excellent option for applications requiring long operational hours or minimal refueling.

- Weight Reduction: With only one engine powering the system, the overall weight is reduced, which is critical for applications like aircraft, where weight savings are vital.

Limitations of Single-Engine Systems

Despite their advantages, single-engine systems also come with a few limitations, including:

- Reduced Redundancy: In applications like aviation, relying on a single engine can be risky, especially in critical situations. If the engine fails, the entire system is compromised.

- Limited Power Output: For heavy-duty applications, single-engine systems may not provide the required power output, which is why larger machinery or commercial vehicles often use multi-engine setups.

Conclusion

In conclusion, single-engine systems are a vital component in the fields of aviation, automotive engineering, and small machinery. Their simplicity, cost-effectiveness, and fuel efficiency make them an ideal choice for many applications. Whether it’s powering a light aircraft, a compact car, or a lawnmower, the single-engine continues to play a pivotal role in shaping the technology that powers our everyday lives.

Understanding the working principles and the different configurations of single-engine systems, such as inline engines, flat engines, or rotary engines, allows engineers to select the best system for specific tasks, ensuring optimal performance and reliability. As technology continues to evolve, the single-engine system remains a crucial piece of engineering, adaptable to new advancements and innovations in the mechanical world.