Split-phase motors are a common type of single-phase induction motor used extensively in light-duty applications due to their simple construction, reliable performance, and affordability. These motors are often employed in household appliances, small machinery, and other tools where moderate starting torque and efficiency are sufficient. Despite the rise of more complex motor types in recent decades, the split-phase motor remains relevant in various settings due to its unique operating characteristics.

To truly understand how split-phase motors function, it is essential to delve into their internal components, working principle, operating conditions, and typical use cases. This article will explore the detailed operation of split-phase motors, compare them with other types of motors, and address frequently asked questions for better clarity.

1. What Is a Split-Phase Motor?

A split-phase motor, also known as a resistance-start induction motor, is a type of single-phase motor that uses an auxiliary winding to create a phase difference for generating starting torque. This auxiliary or “start” winding is temporarily engaged when the motor begins to rotate and is disconnected once the motor reaches a certain speed, typically 70–80% of its rated speed.

Split-phase motors are designed for systems where the motor doesn’t need to start under heavy load. They are widely utilized in applications such as:

- Washing machines

- Small woodworking equipment

- Air compressors

- Blowers and fans

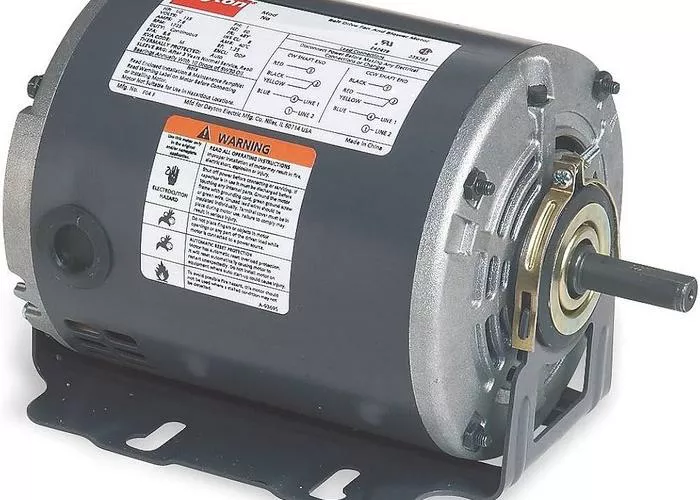

2. Basic Construction of a Split-Phase Motor

The core construction of a split-phase motor includes:

Stator: Houses the main and auxiliary windings.

Rotor: Generally of the squirrel cage type.

Centrifugal Switch or Relay: Disconnects the auxiliary winding once the motor reaches a preset speed.

Frame: Encases and protects internal components.

Bearings: Allow smooth rotation of the rotor.

The stator contains two windings:

Main Winding: Also called the running winding, it has a lower resistance and higher inductance.

Auxiliary Winding: Positioned 90 electrical degrees apart from the main winding, it has higher resistance and lower inductance to create a phase shift necessary for starting torque.

3. How Does a Split-Phase Motor Work?

When the motor is powered, alternating current flows through both the main and auxiliary windings. Due to their differing electrical characteristics, a phase shift occurs between the currents flowing in these windings. This phase difference results in a rotating magnetic field that initiates the rotation of the rotor.

Here’s a step-by-step explanation:

1. Start-Up Phase:

Both the main and auxiliary windings are energized.

A phase difference is established, generating a rotating magnetic field.

The rotor, typically a squirrel cage induction motor type, begins to rotate.

2. Switching Mechanism:

As the rotor speed increases, the centrifugal switch or current-sensitive relay is activated.

Once the motor reaches around 75% of its full speed, the auxiliary winding is disconnected from the circuit.

3. Running Phase:

The motor continues to operate using only the main winding.

Since there is no ongoing phase shift, the motor operates with slightly reduced efficiency and torque.

4. Operating Characteristics of Split-Phase Motors

Split-phase motors offer specific operating characteristics that make them suitable for certain types of loads:

Starting Torque: Moderate (typically 150–200% of full-load torque)

Running Torque: Adequate for low to medium-load applications

Efficiency: Lower compared to polyphase or capacitor-type motors

Current Draw: High during startup; normalizes after auxiliary winding disconnects

Maintenance: Low, with minimal mechanical components involved

5. Advantages of Split-Phase Motors

Split-phase motors present numerous benefits for users looking for reliable and cost-effective solutions in light-load operations:

Simplicity: Straightforward design and ease of manufacturing.

Cost-Effective: Economical in both production and operation.

Low Maintenance: With fewer components, especially in the rotor, the motor is less prone to mechanical failure.

Availability: Widely accessible and supported by most industrial suppliers.

6. Limitations of Split-Phase Motors

However, split-phase motors are not ideal for every situation. Their limitations include:

Limited Starting Torque: Unsuitable for high-torque requirements at start.

Intermittent Duty: Not ideal for continuous heavy-duty cycles.

Noise: Can be noisier than capacitor-start motors.

Thermal Constraints: The auxiliary winding and centrifugal switch must be well managed to prevent overheating.

7. Split-Phase Motor vs. Other Induction Motors

It’s helpful to understand how split-phase motors differ from other commonly used induction motors:

Split-Phase vs. Capacitor-Start Motors:

Capacitor-start motors offer higher starting torque due to the capacitor’s improved phase angle separation.

Split-phase motors are less expensive but also less powerful in startup conditions.

Split-Phase vs. Three-Phase Motors:

Three-phase motors are more efficient, reliable, and powerful but require a three-phase power supply.

Split-phase motors work on standard single-phase household circuits.

Split-Phase vs. Wound Rotor Induction Motors:

Wound rotor motors offer variable speed control and higher starting torque.

Split-phase motors are simpler and designed for fixed speed operations.

8. Applications of Split-Phase Motors

Due to their moderate torque and economical design, split-phase motors are used in applications where heavy start loads are not required. Some practical uses include:

- Domestic water pumps

- Small conveyors

- Bench grinders

- Office equipment such as duplicators

- Residential HVAC blower motors

9. Efficiency and Thermal Considerations

Split-phase motors are generally less efficient than capacitor-start or polyphase motors. Their efficiency ranges between 55–65%, which is adequate for intermittent-use applications. Thermal design is critical, as the auxiliary winding and switch can be susceptible to failure if the motor is frequently cycled or overloaded.

To counter these challenges, modern motor designs often include thermal overload protection, improved insulation, and ventilation enhancements.

10. Maintenance and Troubleshooting

Split-phase motors require relatively little maintenance. Common issues and their possible causes include:

Failure to Start:

- Faulty centrifugal switch

- Damaged start winding

- Capacitor issue (in modified versions with capacitors)

Unusual Noise or Vibration:

- Worn bearings

- Rotor imbalance

- Misalignment

Overheating:

- Continuous heavy load

- Blocked ventilation

- Electrical fault in winding

Regular inspection and basic preventive maintenance can significantly extend the motor’s service life.

11. Evolution and Modern Trends

Although newer motor technologies such as variable frequency drives (VFDs) and electronically commutated motors (ECMs) are becoming more prevalent, split-phase motors still maintain a firm position in cost-sensitive and basic automation environments. Improvements in insulation materials, thermal management, and compact motor design have made split-phase motors more robust and adaptable to modern expectations.

12. Integration into Electrical Systems

Split-phase motors are commonly integrated into larger electrical equipment frameworks. Their compatibility with standard single-phase power and minimal control requirements make them ideal for residential and light commercial electrical setups. Some systems incorporate basic motor controllers or start-delay timers to enhance motor performance.

13. Related Concepts and Motor Types

Understanding split-phase motors provides a foundation for studying other motor types such as:

Single-Phase Induction Motors: Broader category encompassing various single-phase motors including split-phase, capacitor-start, and shaded-pole motors.

Synchronous Motors: Operate at constant speed regardless of load, using magnetic locking with stator field.

Three-Phase Squirrel Cage Induction Motors: Widely used in industrial settings for their ruggedness and efficiency.

Conclusion

Split-phase motors continue to serve a critical role in various low to moderate-load applications where simplicity, affordability, and dependability are key. Their fundamental operating principle—utilizing two windings to generate a phase shift for startup—remains a brilliant application of basic electrical engineering. While advanced motor technologies are emerging, the split-phase motor remains a go-to solution for engineers and technicians seeking reliable performance without complexity.

By understanding its construction, operation, and practical uses, professionals can make informed decisions on when and how to deploy this time-tested motor design.

FAQs

Q1: Can split-phase motors be reversed?

Yes, reversing a split-phase motor involves interchanging the connections of either the start or the run winding, but not both. This changes the direction of the rotating magnetic field, causing the rotor to turn in the opposite direction.

Q2: Are split-phase motors suitable for continuous operation?

Split-phase motors are better suited for intermittent or light-duty continuous operation. They are not ideal for continuous heavy-load conditions due to thermal limitations and modest efficiency.

Q3: Why is a centrifugal switch necessary?

The centrifugal switch disconnects the auxiliary winding once the motor reaches a predetermined speed. This prevents overheating of the start winding, which is not designed for continuous use.

Q4: Can I replace a split-phase motor with a capacitor-start motor?

Yes, capacitor-start motors can often replace split-phase motors if higher starting torque is needed. However, ensure compatibility with the mechanical and electrical system before replacement.

Q5: What is the typical lifespan of a split-phase motor?

With proper maintenance and under suitable loading conditions, split-phase motors can last 10–15 years or more. Overheating, frequent starts, or exposure to harsh environments can shorten their lifespan.