Chemical sensors are devices that detect, identify, and quantify chemical substances within an environment. Their applications span across industries such as environmental monitoring, healthcare, food safety, industrial process control, and homeland security. Fundamentally, chemical sensors serve as critical tools in transforming chemical information—often present in complex mixtures—into readable and actionable signals. This capability enables real-time, on-site analysis and continuous monitoring that is otherwise impossible or impractical through conventional laboratory methods.

Understanding chemical sensors requires a multidisciplinary approach, combining elements of chemistry, materials science, electronics, and engineering. At their core, chemical sensors rely on the interaction between a sensing element and the target analyte to produce a measurable physical or chemical change. This article explores the principles behind chemical sensors, their working mechanisms, various types, and practical applications, providing a comprehensive understanding of these vital instruments.

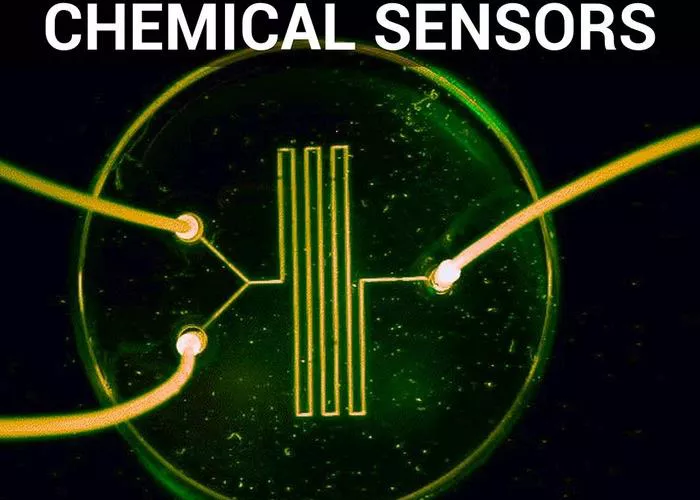

Fundamental Principles of Chemical Sensing

A chemical sensor consists of two main components: the receptor and the transducer. The receptor is responsible for selective interaction with the target chemical species, while the transducer converts this interaction into a measurable signal, such as an electrical output. This conversion is key to enabling further data processing and interpretation.

The Receptor: Selectivity and Sensitivity

The receptor element’s primary role is to selectively bind or interact with specific analytes amid numerous other chemical species. Achieving selectivity often involves molecular recognition mechanisms such as adsorption, absorption, chemical reaction, or molecular imprinting. Sensitivity refers to the receptor’s ability to detect low concentrations of the analyte, which is influenced by its chemical affinity, surface area, and physical structure.

The Transducer: Signal Conversion

Once the receptor interacts with the analyte, this event must be converted into a quantifiable signal. The transducer translates chemical information into electrical, optical, thermal, or mechanical signals depending on the sensor type. Electrical transducers are most common, leveraging variations in current, voltage, resistance, or capacitance as indicators of chemical presence and concentration.

Classification of Chemical Sensors

Chemical sensors are broadly classified based on their transduction mechanism and the nature of the sensing material. Understanding these classifications aids in selecting the appropriate sensor for specific applications.

Electrochemical Sensors

Electrochemical sensors measure changes in electrical properties caused by chemical reactions at the electrode interface. They include potentiometric, amperometric, and conductometric sensors:

- Potentiometric sensors detect changes in voltage related to ion concentration. The classic example is the pH sensor, which measures hydrogen ion activity.

- Amperometric sensors measure current generated by the redox reaction of the analyte at the electrode surface.

- Conductometric sensors monitor variations in electrical conductivity caused by changes in the ionic content of the medium.

Optical Sensors

Optical chemical sensors use light as a transduction medium. The presence of an analyte alters the optical properties of a sensing layer, such as absorbance, fluorescence, or refractive index. Techniques such as surface plasmon resonance and fiber-optic sensing fall into this category, enabling highly sensitive and non-invasive measurements.

Mass-Sensitive Sensors

These sensors detect changes in mass resulting from analyte adsorption on a sensitive surface. Examples include quartz crystal microbalances (QCM) and surface acoustic wave (SAW) sensors. The increase in mass causes a measurable shift in the resonant frequency, proportional to the analyte concentration.

Thermal Sensors

Thermal sensors rely on heat changes induced by chemical reactions or adsorption processes. The thermal effect can be exothermic or endothermic, detected by thermistors or thermocouples integrated into the sensor.

How Chemical Sensors Work

The core working mechanism of chemical sensors involves the transduction of a chemical interaction into a detectable signal. The following processes describe the sequence of events typically occurring within a chemical sensor:

1. Analyte Diffusion and Interaction

The target chemical species diffuse toward the receptor surface, where selective binding or reaction takes place. Factors influencing this step include analyte concentration, temperature, pressure, and receptor surface properties such as porosity and functional groups.

2. Chemical Recognition and Binding

Upon contact, specific chemical interactions—such as hydrogen bonding, ionic interactions, covalent bonding, or van der Waals forces—occur between the analyte and receptor molecules. This interaction changes the receptor’s physicochemical properties.

3. Signal Generation by the Transducer

The altered receptor state is converted into an electrical, optical, or mechanical signal. For example, in an electrochemical sensor, electron transfer events generate measurable currents, while in optical sensors, changes in fluorescence intensity or wavelength shift provide the signal.

4. Signal Processing and Output

The raw signal often requires amplification, filtering, and digitization to provide meaningful output. Advanced sensors integrate microcontrollers and software algorithms to improve sensitivity, selectivity, and enable data logging or wireless transmission.

Materials Used in Chemical Sensors

The choice of materials for the receptor and transducer directly affects sensor performance. Advances in nanotechnology and material science have introduced novel materials with superior sensitivity and selectivity.

Metal Oxides

Metal oxide semiconductors such as tin oxide (SnO2), zinc oxide (ZnO), and titanium dioxide (TiO2) are widely used for gas sensing. Their conductivity changes in response to gas adsorption, making them popular in environmental and industrial applications.

Conductive Polymers

Polymers like polyaniline and polypyrrole offer advantages such as flexibility, low cost, and tunable properties. They are often employed in sensors detecting volatile organic compounds and biological molecules.

Nanomaterials

Nanoparticles, nanotubes, and graphene derivatives provide high surface area and unique electrical properties. Their incorporation enhances sensitivity and lowers detection limits, making them attractive for next-generation sensors.

Bioreceptors

In biosensors, biological elements such as enzymes, antibodies, or nucleic acids serve as receptors, enabling highly selective detection of biomolecules and pathogens.

Applications of Chemical Sensors

Chemical sensors have revolutionized numerous fields by enabling precise and rapid chemical analysis. Below are key application areas:

Environmental Monitoring

Monitoring pollutants like carbon monoxide, nitrogen oxides, and volatile organic compounds is critical for air quality management. Chemical sensors allow continuous, real-time detection with high sensitivity, facilitating regulatory compliance and public health protection.

Medical Diagnostics

In healthcare, sensors are used to detect biomarkers in blood, breath, or bodily fluids, aiding early disease diagnosis and personalized medicine. For example, glucose sensors have transformed diabetes management by enabling frequent and non-invasive blood sugar monitoring.

Food Safety and Quality Control

Chemical sensors help detect contaminants, toxins, and spoilage indicators in food products, ensuring consumer safety and maintaining quality standards throughout the supply chain.

Industrial Process Control

In manufacturing, sensors monitor chemical concentrations, humidity, and toxic gases to optimize processes, enhance safety, and reduce emissions.

Security and Defense

Chemical sensors are vital for detecting explosives, chemical warfare agents, and toxic industrial chemicals, contributing to homeland security and emergency response preparedness.

Conclusion

Chemical sensors are indispensable tools that bridge the gap between complex chemical environments and actionable information. By harnessing selective chemical interactions and advanced transduction mechanisms, these sensors enable real-time, accurate, and often portable chemical analysis. Their diverse applications across environmental monitoring, healthcare, industry, and security underscore their critical importance.

As technology evolves, chemical sensors will continue to become more sensitive, selective, and integrated with digital systems, expanding their capabilities and usability. Understanding their principles and working mechanisms is essential for engineers, scientists, and decision-makers aiming to leverage these devices effectively in various fields.

FAQs

What is the difference between a chemical sensor and a biosensor?

A chemical sensor detects chemical substances generally, while a biosensor specifically uses biological elements (like enzymes or antibodies) as receptors to detect biomolecules, pathogens, or biological analytes.

How do chemical sensors achieve selectivity for specific analytes?

Selectivity is achieved through the design of the receptor material, which can selectively bind or react with certain molecules based on size, shape, chemical affinity, or molecular recognition techniques.

Can chemical sensors detect multiple chemicals simultaneously?

Yes, some advanced sensors are designed as arrays with multiple sensing elements, each targeting different analytes. Signal processing techniques then deconvolute the combined responses.

What factors influence the sensitivity of a chemical sensor?

Sensitivity depends on receptor material properties (surface area, affinity), transducer efficiency, environmental conditions (temperature, humidity), and the sensor’s design and fabrication quality.

Are chemical sensors reusable or disposable?

Both types exist. Some sensors are designed for continuous, long-term use, while others are disposable, particularly in medical diagnostics, to avoid contamination and maintain accuracy.