Pressure measurement plays a critical role in numerous industries such as manufacturing, aerospace, automotive, and medical devices. Accurately gauging pressure is essential for controlling processes, ensuring safety, and optimizing system performance. Among the many devices used for this purpose, diaphragm pressure transducers are notable for their precision and reliability. These sensors convert pressure into an electrical signal that can be measured, monitored, and recorded.

What is a Diaphragm Pressure Transducer?

A diaphragm pressure transducer is a sensor that measures pressure by using the deformation of a diaphragm. The diaphragm is a thin, flexible membrane that deflects when subjected to pressure. This deflection is then converted into an electrical signal through various methods, depending on the type of transducer. These sensors are especially useful for low-pressure applications or when cleanliness and isolation from the media are essential.

Key Components of a Diaphragm Pressure Transducer

To understand how a diaphragm pressure transducer works, it is important to familiarize oneself with its core components:

- Diaphragm: Typically made of metal, silicon, or polymer, this membrane is the primary sensing element.

- Sensing Element: Converts diaphragm deflection into an electrical signal. Common types include strain gauges, piezoresistive elements, or capacitive sensors.

- Housing: Encases the diaphragm and protects it from environmental damage.

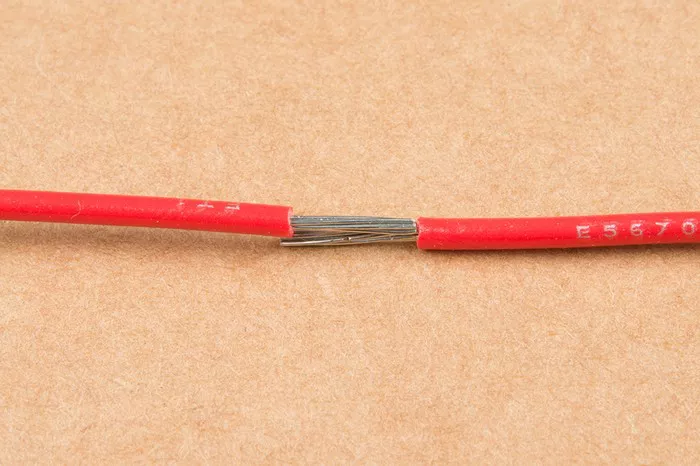

- Electrical Connections: Transmit the signal to external data acquisition or monitoring systems.

These components work in harmony to ensure that pressure changes are accurately detected and converted into usable data.

How a Diaphragm Pressure Transducer Works

The working principle of a diaphragm pressure transducer revolves around the physical deformation of the diaphragm due to applied pressure. Here’s a step-by-step overview of how it works:

- Pressure Application: When pressure is applied to the diaphragm, it deflects proportionally to the magnitude of the pressure.

- Deformation Sensing: The sensing element, which is in contact with the diaphragm, detects this deformation.

- Signal Conversion: The mechanical deformation is transformed into an electrical signal. The method of conversion depends on the transducer type.

- Signal Transmission: The electrical signal is then sent to a processing unit where it can be displayed, recorded, or used for control.

This process is instantaneous and continuous, allowing real-time pressure monitoring.

Types of Diaphragm Pressure Transducers

Diaphragm pressure transducers can be classified based on their sensing mechanism. The main types include:

1. Strain Gauge-Based

These use strain gauges bonded to the diaphragm. When pressure causes the diaphragm to flex, the strain gauges deform, changing their electrical resistance. This change is measured and correlated to pressure.

2. Capacitive

In capacitive transducers, the diaphragm acts as one plate of a capacitor. As pressure changes the diaphragm’s position, the capacitance between the plates changes, which is then measured and converted into pressure readings.

3. Piezoresistive

This type uses piezoresistive materials embedded in or on the diaphragm. These materials change their resistance when stressed, allowing for pressure detection.

4. Optical and Resonant

Less common but highly precise, these methods involve detecting diaphragm movement through optical changes or frequency shifts in resonating elements.

Advantages of Diaphragm Pressure Transducers

Using diaphragm-based pressure transducers offers several benefits, which include:

- High Accuracy: Excellent precision in both low and high-pressure ranges.

- Good Linearity: Ensures predictable output over the entire operating range.

- Durability: Robust designs withstand harsh environments.

- Versatility: Applicable to gases, liquids, and corrosive media.

- Miniaturization: Compact designs suitable for embedded applications.

These features make diaphragm pressure transducers ideal for demanding industrial and scientific environments.

Applications of Diaphragm Pressure Transducers

Diaphragm pressure transducers are widely used in various fields. Some notable applications include:

- Medical Devices: Monitoring blood pressure or respiratory pressure in ventilators.

- Automotive Industry: Measuring fuel, brake, and manifold pressures.

- Aerospace: Cabin pressure monitoring and hydraulic system testing.

- Food and Beverage Industry: Sanitary pressure measurements in processing equipment.

- Oil and Gas: Monitoring pressures in pipelines and drilling operations.

Their ability to function in both sterile and extreme environments makes them indispensable tools.

Factors to Consider When Choosing a Diaphragm Pressure Transducer

Selecting the right diaphragm pressure transducer involves careful consideration of several factors:

- Pressure Range: Ensure compatibility with the expected pressure levels.

- Media Compatibility: Choose diaphragm materials that can resist corrosion or contamination.

- Environmental Conditions: Consider temperature, humidity, and potential exposure to chemicals.

- Signal Output: Match with your data acquisition system (analog, digital, etc.).

- Accuracy and Stability: Higher precision may be necessary for sensitive applications.

Proper selection ensures reliable and long-lasting performance.

Installation and Maintenance

Correct installation and maintenance of diaphragm pressure transducers are essential for optimal operation. Here are some best practices:

- Proper Mounting: Follow manufacturer guidelines to avoid mechanical stress.

- Seal Integrity: Ensure leak-proof connections, especially in fluid systems.

- Regular Calibration: Periodically calibrate the sensor to maintain accuracy.

- Environmental Protection: Use protective housings in harsh environments.

- Avoid Overpressure: Prevent exposure to pressure levels beyond the sensor’s rating.

These practices minimize downtime and extend the life of the sensor.

Limitations and Challenges

While diaphragm pressure transducers are highly effective, they do have certain limitations:

- Temperature Sensitivity: Extreme temperatures can affect accuracy.

- Fragility of Thin Diaphragms: May be susceptible to damage from physical impact.

- Signal Drift: Over time, the sensor may need recalibration.

- Cost: High-precision models can be relatively expensive.

Being aware of these limitations helps users implement necessary safeguards.

Conclusion

Diaphragm pressure transducers are indispensable in today’s technologically advanced world. Their ability to convert mechanical pressure into accurate electrical signals makes them a cornerstone in countless applications. By understanding their structure, working principles, and application nuances, users can make informed decisions that enhance performance and reliability. As technology progresses, diaphragm pressure transducers will undoubtedly play a vital role in the future of precision pressure measurement.

FAQs

What materials are commonly used for diaphragms in pressure transducers?

Common materials include stainless steel, silicon, and various polymers. The choice depends on the application’s pressure range, media compatibility, and required durability.

Can diaphragm pressure transducers be used with corrosive fluids?

Yes, but it’s essential to select a diaphragm material and housing that are chemically compatible with the fluid to prevent degradation and ensure accurate readings.

How often should a diaphragm pressure transducer be calibrated?

Calibration frequency depends on the application and required accuracy. For critical applications, calibration every 6 to 12 months is common.

Are these sensors suitable for high-pressure applications?

Yes, diaphragm pressure transducers can be designed for both low and high-pressure applications. However, care must be taken to avoid exceeding the sensor’s maximum rated pressure.

How does temperature affect diaphragm pressure transducers?

Temperature variations can cause changes in material properties, potentially affecting accuracy. Some sensors include temperature compensation features to mitigate this.

Can diaphragm pressure transducers be used in medical devices?

Yes, they are widely used in applications such as blood pressure monitoring and respiratory equipment due to their accuracy and sensitivity.

What kind of output signals do diaphragm pressure transducers provide?

They can provide analog signals (voltage or current) or digital outputs, depending on the design and application needs.

Are diaphragm pressure transducers affected by vibration?

Prolonged or intense vibration can potentially impact sensor performance. Vibration-resistant designs are available for such conditions.

What certifications should I look for when choosing a diaphragm pressure transducer?

Look for certifications such as ISO, CE, or those required by specific industries (e.g., FDA for medical, ATEX for hazardous environments).