Zirconia oxygen sensors are critical components in modern combustion and emission control systems. Known for their durability and precision, these sensors play a fundamental role in monitoring and optimizing oxygen levels in exhaust gases. This capability ensures efficient fuel combustion, reduces harmful emissions, and enhances engine performance. Understanding the principles behind zirconia oxygen sensors, their construction, and operational mechanisms is essential for professionals in automotive engineering, industrial instrumentation, and environmental technology sectors.

What is a Zirconia Oxygen Sensor?

A zirconia oxygen sensor, often referred to as a lambda sensor, is an electrochemical device that measures the oxygen concentration in gases, primarily exhaust gases from internal combustion engines. It uses a solid electrolyte made from zirconium dioxide (ZrO2) stabilized with yttria (Y2O3), commonly known as yttria-stabilized zirconia (YSZ). This ceramic material exhibits excellent ionic conductivity at high temperatures, typically above 300°C, which makes it suitable for harsh environments such as vehicle exhaust streams.

The sensor provides real-time feedback about the air-fuel mixture, enabling engine management systems to adjust fuel injection for optimal combustion. This closed-loop control is fundamental to meeting stringent emission regulations while maintaining fuel efficiency.

Historical Development and Applications

The invention of the zirconia oxygen sensor dates back to the 1960s, pioneered by Dr. Günter Bauman, who developed the first practical lambda sensor. Since then, zirconia sensors have become industry standards in automotive exhaust systems and have found applications in industrial combustion processes, environmental monitoring, and instrumentation.

In automotive applications, zirconia sensors are embedded in the exhaust manifold or catalytic converter housing. Beyond automotive use, they are integral in industrial furnaces, gas turbines, and boilers where oxygen levels directly impact process efficiency and emission compliance.

Key Components and Structure

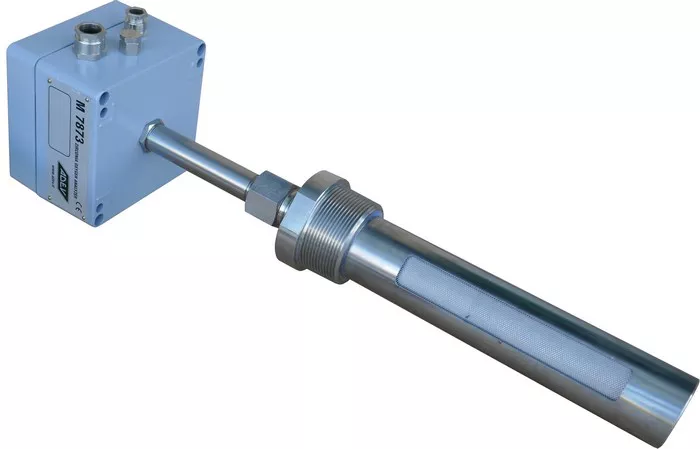

The core of a zirconia oxygen sensor is the ceramic electrolyte pellet made from stabilized zirconia. This pellet is sandwiched between two porous electrodes—commonly platinum—which facilitate the electrochemical reactions with oxygen ions.

- Electrolyte: The yttria-stabilized zirconia pellet serves as the oxygen ion conductor.

- Electrodes: Porous platinum electrodes on both sides enable oxygen adsorption and ionization.

- Protective Housing: The sensor is enclosed in a stainless steel casing that protects the sensor from mechanical damage and contaminants.

- Heater Element: Many sensors include an internal heater to quickly bring the sensor to operating temperature, ensuring accurate measurements.

How Zirconia Oxygen Sensors Work: Electrochemical Principles

The working principle of zirconia oxygen sensors is based on the difference in oxygen partial pressure between the exhaust gas and the ambient air. At high temperatures, oxygen ions (O2−) can move through the zirconia electrolyte, creating an electrochemical potential difference measurable as a voltage.

Electrochemical Reaction and Nernst Equation

The sensor operates according to the Nernst equation, which relates the voltage output to the ratio of oxygen partial pressures on either side of the electrolyte:

E = (RT / 4F) * ln(PO2,air / PO2,exhaust)

Where:

- E is the electromotive force (voltage) generated by the sensor.

- R is the universal gas constant.

- T is the temperature in Kelvin.

- F is the Faraday constant.

- PO2,air and PO2,exhaust are the partial pressures of oxygen in ambient air and exhaust gas, respectively.

Because the partial pressure of oxygen in ambient air is relatively constant, changes in exhaust oxygen levels cause proportional changes in the sensor voltage. A typical sensor voltage ranges from 0.1 V (lean mixture) to 0.9 V (rich mixture), with 0.45 V corresponding to the stoichiometric air-fuel ratio.

Ion Transport Mechanism

At the sensor’s operating temperature, oxygen molecules at the exhaust side are ionized at the electrode, releasing oxygen ions that travel through the zirconia electrolyte to the air side electrode. This ion transport generates a measurable voltage difference due to the different oxygen concentrations.

Types of Zirconia Oxygen Sensors

Zirconia sensors are broadly classified into two types based on their operation and output characteristics:

1. Narrow-Band Zirconia Sensors

These sensors produce a voltage output that sharply changes near the stoichiometric air-fuel ratio (around 14.7:1 for gasoline engines). They are widely used in automotive closed-loop fuel control systems but do not provide precise measurement over a wide oxygen range.

2. Wide-Band Zirconia Sensors

Also known as air-fuel ratio (AFR) sensors, wide-band sensors provide a linear output across a broad range of air-fuel mixtures. They include an internal pump cell that actively controls oxygen ion flow, allowing more precise control and monitoring. Wide-band sensors are crucial for modern engines requiring strict emission controls and advanced combustion management.

Installation and Operational Conditions

Correct installation and operational conditions are vital for sensor longevity and accuracy. Zirconia oxygen sensors must operate at elevated temperatures (typically 300–800°C) to ensure ionic conductivity. Therefore, they often include built-in heaters to reduce warm-up time.

The sensor is usually installed in the exhaust stream downstream of the engine’s combustion chamber or catalytic converter to monitor oxygen levels in the exhaust gas directly. Placement affects response time and measurement accuracy.

Advantages of Zirconia Oxygen Sensors

- High Accuracy: Provides precise oxygen concentration measurements necessary for optimal engine control.

- Fast Response: Rapid voltage changes near stoichiometric conditions enable timely engine adjustments.

- Durability: Resistant to high temperatures and exhaust gas contaminants.

- Wide Application Range: Used in automotive, industrial, and environmental instrumentation.

Challenges and Limitations

Despite their widespread use, zirconia oxygen sensors have some limitations:

- Temperature Dependence: Performance depends heavily on operating temperature; sensor failure can occur if the heater malfunctions.

- Limited Life Span: Exposure to contaminants like lead, sulfur, or silicon can degrade sensor performance over time.

- Non-Linearity in Narrow-Band Sensors: Narrow-band sensors provide limited data resolution outside the stoichiometric point.

Comparison with Other Oxygen Sensing Technologies

While zirconia sensors dominate automotive oxygen sensing, other technologies such as titania sensors and electrochemical gas sensors also exist. However, zirconia’s robustness, sensitivity, and operational temperature range give it distinct advantages.

Furthermore, zirconia oxygen sensors are often integrated alongside other sensor types in instrumentation systems, such as pressure sensors and instrumentation tools, to provide comprehensive data for combustion optimization and emission monitoring.

Maintenance and Troubleshooting

Routine inspection and calibration of zirconia oxygen sensors are essential to maintain system performance. Common issues include sensor contamination, wiring faults, and heater element failure. Symptoms of sensor malfunction include erratic voltage output, delayed response, and poor engine performance.

Replacement intervals vary but generally range from 60,000 to 100,000 miles in automotive applications. Using diagnostic tools to monitor sensor voltage and heater resistance aids in early fault detection.

Conclusion

Zirconia oxygen sensors are indispensable components in modern combustion systems, providing vital data to optimize air-fuel mixtures for performance, fuel efficiency, and emissions control. Their high-temperature ionic conduction properties, combined with robust ceramic materials, enable accurate and reliable oxygen measurement in challenging environments. Although challenges such as sensor degradation and temperature dependency exist, ongoing advancements continue to enhance their capabilities and applications.

For professionals engaged in automotive engineering, industrial combustion control, or environmental instrumentation, a thorough understanding of zirconia oxygen sensor technology is crucial for system design, maintenance, and innovation.

FAQs

What is the main function of a zirconia oxygen sensor?

Its primary function is to measure the oxygen concentration in exhaust gases to help control the air-fuel mixture in combustion engines for optimal efficiency and reduced emissions.

How does the sensor voltage relate to oxygen levels?

The sensor voltage is generated by the difference in oxygen partial pressure between exhaust gas and ambient air, with higher voltage indicating a richer mixture (less oxygen) and lower voltage indicating a leaner mixture (more oxygen).

Why do zirconia sensors require high operating temperatures?

Zirconia’s ionic conductivity increases significantly at high temperatures (above 300°C), allowing oxygen ions to move through the electrolyte and generate an electrochemical voltage.

What is the difference between narrow-band and wide-band zirconia sensors?

Narrow-band sensors provide a voltage output that sharply switches near the stoichiometric ratio, suitable for basic engine control. Wide-band sensors offer a linear and more precise measurement across a broader air-fuel range, used in advanced engine management.

Can zirconia oxygen sensors be used in industrial applications?

Yes, they are widely used in industrial combustion processes, such as in furnaces and boilers, for monitoring oxygen levels to ensure process efficiency and regulatory compliance.