Transformers are indispensable components in the realm of electrical equipment, playing a critical role in voltage regulation, power distribution, and electrical isolation. Despite their robust design, transformers are susceptible to failures, often resulting in burnout—a catastrophic event that can disrupt power systems and incur significant repair costs. Understanding the situations that lead to transformer burnout is essential for engineers, maintenance personnel, and facility managers aiming to enhance system reliability and prolong transformer life.

This article delves deeply into the 11 most common situations that can cause transformer burnout. These scenarios encompass electrical, mechanical, and environmental factors, providing a comprehensive view of transformer vulnerabilities. We will also highlight preventative measures and maintenance tips to mitigate these risks.

1. Overloading Beyond Rated Capacity

One of the primary causes of transformer burnout is operating the transformer beyond its rated load capacity. Transformers are designed to handle a specific maximum current and voltage. Exceeding this capacity causes excessive heat generation within the winding insulation and core, accelerating insulation degradation and leading to thermal breakdown. Persistent overloading can cause hotspots, insulation failure, and ultimately burnout.

For example, a step-up transformer designed to increase voltage for transmission lines may fail if it is forced to deliver loads far beyond its rating. Proper load monitoring and implementing automatic load shedding are key preventive actions.

2. Short Circuits and Electrical Faults

Short circuits in transformer windings or the connected electrical network cause sudden surges in current, which can produce severe internal damage. The resulting intense magnetic fields generate mechanical stresses and significant heat. Fault currents can lead to conductor melting, insulation puncture, and arcing, which ultimately causes the transformer to burn out.

Routine testing for insulation resistance and circuit integrity, combined with protective relays, can help detect and isolate faults promptly to avoid transformer damage.

3. Insulation Deterioration Over Time

The insulation system inside transformers—typically composed of oil and solid insulating materials—deteriorates gradually due to thermal aging, moisture ingress, and chemical contamination. Compromised insulation reduces dielectric strength, making the transformer vulnerable to internal arcing and partial discharge. Over time, these microscopic electrical discharges degrade insulation until catastrophic failure occurs.

Regular dissolved gas analysis (DGA) and insulation resistance testing provide valuable diagnostics to detect insulation weakening before it results in burnout.

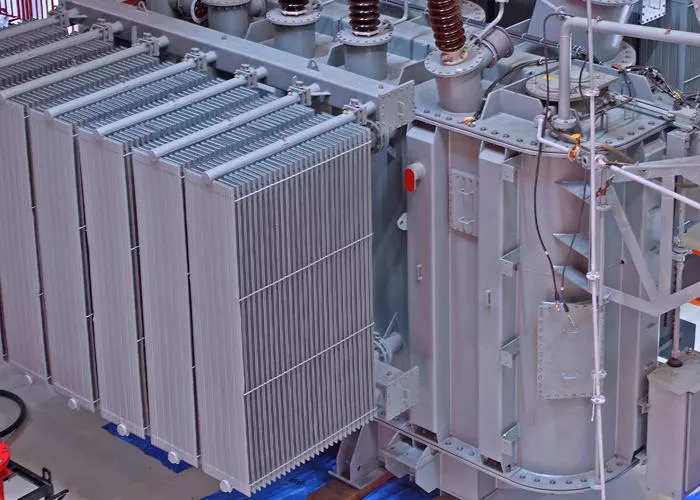

4. Overheating from Cooling System Failures

Transformers rely heavily on efficient cooling mechanisms—oil or air cooling—to maintain safe operating temperatures. Failures in cooling systems, such as pump breakdowns, blocked cooling fins, or oil leaks, can cause rapid temperature rise inside the transformer. Overheating accelerates insulation aging and may result in the formation of gases within the oil, increasing the risk of explosion or fire.

Maintenance protocols should include frequent inspection of cooling circuits and temperature monitoring with alarms to detect overheating early.

5. Voltage Surges and Lightning Strikes

Voltage spikes due to lightning strikes or switching surges can impose transient overvoltages on transformers. These overvoltages stress the insulation beyond its withstand capacity, causing partial discharges or flashovers. Repeated transient events can erode insulation integrity, leading to eventual burnout.

Installing surge arresters and lightning protection systems is crucial for transformers located outdoors or in high-risk areas.

6. Harmonics and Poor Power Quality

Harmonics generated by non-linear loads (such as variable frequency drives or electronic equipment) can cause increased eddy current and hysteresis losses in transformers. This results in additional heat generation and mechanical vibration, which degrade transformer components over time.

Using compact transformers designed with low losses and harmonic mitigation features can help reduce damage caused by poor power quality.

7. Improper Installation and Mechanical Damage

Improper installation procedures—such as poor connections, incorrect mounting, or insufficient grounding—can create abnormal electrical stresses or mechanical vibrations. These issues increase the likelihood of winding displacement or insulation damage under operational stress, which can precipitate burnout.

Ensuring adherence to manufacturer guidelines and employing qualified personnel during installation minimizes mechanical and electrical faults.

8. Moisture and Contamination Ingress

Moisture entering the transformer tank or insulating oil lowers dielectric strength and promotes corrosion of internal components. Contaminants such as dust, dirt, and chemicals further degrade insulation and may lead to partial discharges.

Maintaining proper sealing, regular oil filtration, and moisture monitoring are essential maintenance practices to prevent transformer burnout from contamination.

9. Aging and Thermal Cycling

Transformers experience thermal expansion and contraction during load cycling, which can induce mechanical stresses in the insulation system. Over many years, repeated thermal cycling combined with general aging weakens insulation bonds and causes micro-cracks or delamination, which eventually results in failure.

Periodic thermal imaging and detailed inspections can detect early signs of thermal fatigue, enabling proactive maintenance.

10. Incorrect Tap Changer Operation

Tap changers regulate transformer output voltage by changing winding taps. Improper operation—such as switching under load without suitable equipment or excessive tap changes—can cause arcing, overheating, and contact wear. These issues damage the winding and insulation system, increasing burnout risk.

Automated tap changers with proper control logic and routine contact inspection reduce these risks.

11. External Environmental Factors

Transformers installed in harsh environments—such as areas with extreme temperatures, high humidity, corrosive atmospheres, or seismic activity—face increased stress on their components. Exposure to salt spray, pollutants, or physical shocks can accelerate deterioration and cause insulation breakdown.

Choosing appropriately rated transformers like high voltage transformers with robust environmental protection features is critical in such locations.

Conclusion

Transformer burnout is a multifaceted issue caused by electrical, mechanical, and environmental stresses. By understanding the 11 key situations detailed above—ranging from overloading and insulation degradation to environmental exposure and operational errors—stakeholders can implement targeted preventive strategies. Regular monitoring, proper installation, routine maintenance, and the use of appropriate transformer types are vital to ensuring reliable and long-lasting transformer operation.

FAQs

Q1: How can I detect early signs of transformer burnout?

Early signs include unusual temperature rise, strange noises, oil discoloration, gas accumulation detected by dissolved gas analysis (DGA), and decreased insulation resistance. Using thermal imaging cameras and regular diagnostic testing helps identify problems early.

Q2: Can harmonic currents really damage transformers?

Yes, harmonic currents increase heat losses due to additional eddy currents and magnetic hysteresis. Over time, this can degrade insulation and cause overheating, leading to transformer failure.

Q3: What role does cooling play in transformer longevity?

Cooling systems maintain safe operating temperatures to prevent thermal degradation of insulation. Efficient cooling extends transformer life and prevents burnout caused by overheating.

Q4: Are all transformers equally susceptible to burnout?

Susceptibility varies based on transformer design, application, and environment. Specialized transformers like power transformers are designed for high loads but still require proper maintenance to avoid burnout.

Q5: How important is maintenance in preventing transformer burnout?

Maintenance is critical. Scheduled inspections, oil testing, cleaning, and repairs reduce the risk of failures. Neglecting maintenance significantly increases the likelihood of transformer burnout.