Transformer oil containment is a critical aspect of electrical infrastructure, particularly when dealing with high-voltage and large-capacity transformers. Containment systems are designed to prevent oil spills from escaping into the environment, protecting both public safety and sensitive ecosystems. For beginners new to the world of power systems and substation design, understanding when containment is required is essential not only for regulatory compliance but also for the safe operation and maintenance of electrical equipment.

This guide provides an in-depth exploration of transformer oil containment requirements, touching on relevant regulations, design considerations, industry best practices, and real-world applications. Whether you’re a new engineer, a facility manager, or simply interested in infrastructure, this article will help you navigate the essentials of this vital topic.

What Is Transformer Oil and Why Contain It?

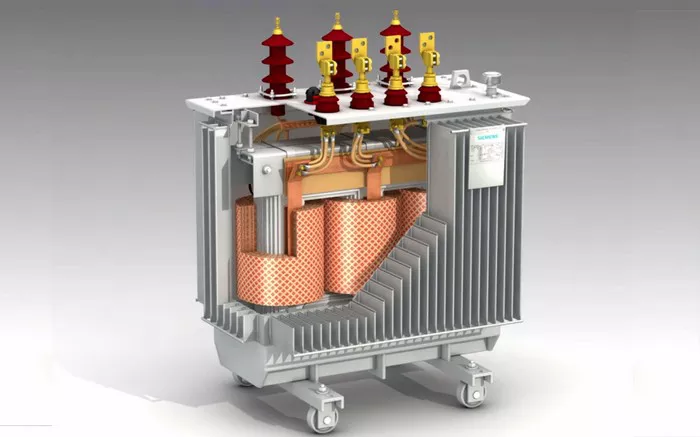

Transformer oil, also known as insulating oil, is a highly refined mineral oil used in oil-filled transformers for insulation and cooling purposes. Its primary functions include:

- Electrical insulation between internal components

- Heat dissipation to prevent overheating

- Suppression of electrical discharges and arcs

However, transformer oil is flammable and classified as a hazardous material. In the event of a leak, rupture, or fire, uncontained oil can contaminate soil and water sources, posing a serious environmental and safety hazard. Thus, containment systems are put in place to intercept and manage potential oil discharges from transformers.

When Is Transformer Oil Containment Required?

Transformer oil containment is typically required in the following scenarios:

1. Based on Oil Volume

Containment is generally mandated when the volume of transformer oil exceeds a threshold, often 660 gallons (approximately 2,500 liters). This is a common benchmark in U.S. EPA regulations and international guidelines. Any transformer with oil capacity above this level should be assessed for containment needs.

2. Location and Environmental Risk

Installations near water bodies, wetlands, or environmentally sensitive areas are prime candidates for containment systems. Even if the oil volume is low, the proximity to ecological zones demands extra caution. Containment helps prevent contamination in the event of a spill or equipment failure.

3. Regulatory Requirements

Different countries have distinct regulatory frameworks. In the U.S., the Environmental Protection Agency (EPA) mandates oil containment under the Spill Prevention, Control, and Countermeasure (SPCC) rule. In the EU, regulations are covered under the Industrial Emissions Directive (IED) and local environmental agency mandates.

4. Facility and Industry Standards

Facilities such as power generation plants, chemical processing units, and large-scale manufacturing often follow internal or industry-specific standards. For instance, the IEEE and NFPA provide guidelines recommending containment measures for transformers handling flammable or hazardous oil.

5. Fire Risk and Public Safety

Urban substations, high-density industrial areas, and public infrastructure locations such as airports or hospitals require transformer oil containment regardless of volume, due to increased fire risk and proximity to people.

Types of Transformer Oil Containment Systems

The choice of containment system depends on the size of the transformer, local regulations, site conditions, and risk assessment outcomes. Here are the most common types:

1. Concrete Bunds or Retaining Walls

These are physical barriers constructed around transformers to contain leaked oil. They are designed to hold at least 110% of the volume of oil in the largest transformer they encircle, as per industry norms.

2. Geomembrane Liners

Used beneath or within bunds, these liners are impermeable membranes that prevent oil from seeping into the ground. Ideal for sites with high water tables or loose soil conditions.

3. Oil-Water Separation Systems

Advanced facilities may include separators that allow rainwater to drain from the containment area while filtering out oil. These systems are essential where containment structures are open to rainfall.

4. Catchment Pits and Drip Trays

Smaller installations or indoor settings may use pits or trays beneath the transformer. These are particularly effective for compact transformers or transformers installed in confined areas.

5. Fire Suppression-Integrated Containment

High-risk sites often integrate fire suppression with containment systems. This includes water spray systems, chemical suppressants, or fire-resistant barriers to control oil fires before they spread.

Design Considerations and Best Practices

Volume and Capacity Planning

Containment should hold at least 110% of the oil in a single transformer or 100% of the largest transformer plus 10% of the total volume of all others in a group. Add additional volume for rainfall if the area is uncovered.

Drainage and Spill Control

Design must include slope and drainage paths to direct oil to collection points or sumps. Drains should be equipped with valves or oil-water separators to prevent uncontrolled discharge.

Accessibility and Maintenance

Ensure containment areas are accessible for inspection, cleaning, and maintenance. Debris accumulation or blocked drains can compromise effectiveness.

Monitoring and Automation

Advanced installations use sensors to detect oil presence, overflow conditions, or fire incidents. Integration with SCADA systems improves response time and reduces risk.

Regulatory Framework Overview

Here’s a breakdown of some key regulatory and guideline sources relevant to transformer oil containment:

- U.S. EPA SPCC Rule (40 CFR Part 112): Requires containment for facilities with over 1,320 gallons of oil in above-ground containers.

- NFPA 850: Recommends fire protection practices including containment design in electric generating plants.

- IEEE Std 980: Provides guidelines on containment and control systems for fluid-filled electrical equipment.

- ISO 14001: Promotes environmental management including risk controls like containment structures.

Environmental and Safety Implications

Failure to implement containment can lead to catastrophic outcomes:

- Soil and groundwater contamination

- Heavy fines and legal liabilities

- Operational downtime and equipment damage

- Increased risk of fire and explosion

Conversely, effective containment mitigates these risks, supports sustainability goals, and ensures long-term operational reliability.

Common Misconceptions

- “Small transformers don’t need containment.” — Even low-volume systems in sensitive locations must have spill control measures.

- “Concrete bunds are enough.” — Without proper drainage or liners, concrete alone may not prevent environmental damage.

- “Indoor transformers are safe.” — Leaks indoors can still pose fire risks and damage structural components.

Conclusion

Transformer oil containment is more than a compliance checkbox—it’s an essential safety and environmental protection strategy. Whether working with a small Single-Phase Transformer or a large substation network, understanding when and how to apply containment practices is crucial. By considering volume, location, regulatory requirements, and risk factors, engineers and operators can design systems that protect both people and the planet.

FAQs

1. Is transformer oil always hazardous?

Yes, transformer oil is classified as a hazardous material due to its flammability and potential for environmental contamination.

2. Do dry-type transformers need containment?

Generally, dry-type transformers do not require oil containment since they do not use insulating oil. However, spill prevention measures may still apply based on local safety standards.

3. How often should containment systems be inspected?

At a minimum, containment systems should be inspected quarterly. Sites with high-risk exposure or previous spills may require more frequent checks.

4. Can I use natural soil as a containment base?

No. Natural soil is porous and cannot reliably contain oil. Geomembrane liners or concrete bases are typically required for compliance and effectiveness.

5. What happens if my transformer oil leaks but I have no containment?

You may face regulatory penalties, cleanup costs, and possible legal action depending on the extent of environmental damage. Immediate reporting and remediation are required by law in most jurisdictions.