Piezoelectric sensors have become a cornerstone technology in various engineering and industrial fields, enabling precise measurement of physical parameters such as pressure, force, acceleration, and vibration. These sensors exploit the piezoelectric effect — a unique property of certain materials that generate an electric charge when subjected to mechanical stress. The technology behind piezoelectric sensors is both elegant and highly practical, providing an interface between the mechanical and electrical worlds.

This article delves deeply into the fundamental principles of piezoelectric sensors, their working mechanisms, materials, design considerations, and diverse applications. By the end, readers will have a clear understanding of how these sensors operate and why they remain essential in modern sensing technology.

The Piezoelectric Effect: The Fundamental Phenomenon

The foundation of piezoelectric sensors lies in the piezoelectric effect, discovered by Pierre and Jacques Curie in 1880. The effect can be described in two complementary ways:

- Direct piezoelectric effect: When mechanical stress is applied to a piezoelectric material, it produces an electrical charge proportional to the applied force.

- Converse piezoelectric effect: When an electrical field is applied to the same material, it causes a mechanical deformation.

Piezoelectric sensors predominantly utilize the direct piezoelectric effect to detect changes in force, pressure, or acceleration by converting them into an electrical signal.

Materials Exhibiting Piezoelectricity

Piezoelectricity is a characteristic of certain crystalline materials that have a non-centrosymmetric structure. The most common piezoelectric materials used in sensors include:

- Quartz (SiO2): One of the earliest known piezoelectric materials, naturally occurring with excellent stability and precision, but relatively low sensitivity compared to synthetic materials.

- Ceramic materials: Lead zirconate titanate (PZT) is widely used due to its high piezoelectric coefficients and ease of manufacturing. Ceramics can be engineered to specific shapes and sizes.

- Polymeric materials: Polyvinylidene fluoride (PVDF) is a flexible piezoelectric polymer used where flexibility and light weight are essential.

- Other crystals: Materials such as tourmaline, gallium orthophosphate, and lithium niobate also exhibit piezoelectricity, often used in specialized applications.

How Piezoelectric Sensors Work: Mechanisms and Operation

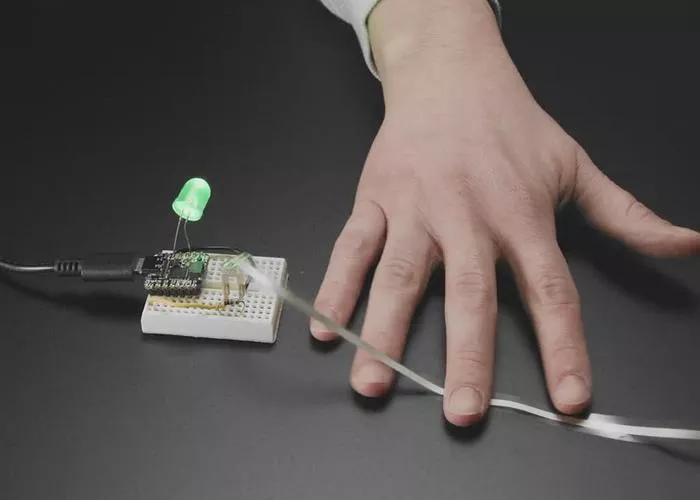

At the heart of the sensor is a piezoelectric element, which may be a thin wafer, film, or ceramic disc. When a mechanical force is applied, the internal crystal lattice of the material deforms, shifting the positions of ions and creating an imbalance of charges. This charge accumulates on the surfaces of the material, generating a measurable voltage.

Since the generated charge is typically very small, piezoelectric sensors incorporate internal or external charge amplifiers to convert the charge into a voltage output suitable for measurement systems. The sensor output voltage is proportional to the applied mechanical stimulus, enabling precise quantification.

Sensor Construction and Design Considerations

The design of a piezoelectric sensor depends on the target measurement and operating environment. Common configurations include:

- Force sensors: Piezoelectric elements are sandwiched between electrodes and housed in a structure to measure compressive or tensile forces.

- Pressure sensors: Often use a diaphragm that transmits pressure to the piezoelectric material, converting it into an electrical signal.

- Accelerometers: Combine a seismic mass with piezoelectric elements to detect inertial forces due to acceleration or vibration.

- Dynamic strain gauges: Measure time-varying strain in structures, machinery, or vehicles.

In addition to material selection, design factors such as temperature compensation, frequency response, sensitivity, durability, and size play critical roles in sensor performance.

Advantages of Piezoelectric Sensors

Piezoelectric sensors offer several compelling benefits that make them suitable for a broad spectrum of applications:

- High sensitivity and accuracy: They provide precise measurements of dynamic forces and vibrations with rapid response times.

- Wide frequency range: Capable of detecting signals from very low frequencies to ultrasonic ranges.

- Ruggedness and durability: Often resistant to harsh environments, including high temperatures, corrosive atmospheres, and mechanical shock.

- No external power required: The direct piezoelectric effect generates voltage without needing an external power supply for sensing.

- Compact and lightweight: Sensors can be miniaturized and embedded into complex systems with minimal impact on size or weight.

Limitations and Challenges

Despite their many strengths, piezoelectric sensors have certain limitations:

- Inability to measure static forces: Since charge slowly dissipates through the material, piezoelectric sensors are best suited for dynamic or rapidly changing forces, not static loads.

- Temperature sensitivity: Some piezoelectric materials show drift or altered performance under extreme temperature variations, requiring compensation mechanisms.

- Signal conditioning complexity: The low charge output necessitates sophisticated electronics for amplification and noise reduction.

Applications of Piezoelectric Sensors

Piezoelectric sensors are used across diverse industries and applications, including but not limited to:

- Automotive: Monitoring engine vibrations, knock sensors, tire pressure sensors, and crash detection.

- Aerospace: Structural health monitoring of aircraft, vibration analysis of engines, and landing gear force measurements.

- Industrial machinery: Condition monitoring, tool wear detection, and process control involving dynamic forces.

- Consumer electronics: Touch-sensitive buttons, microphones, and accelerometers in smartphones and wearable devices.

- Medical devices: Ultrasound transducers, heartbeat monitoring, and respiratory sensors.

- Seismology: Detecting ground vibrations and earthquakes.

Conclusion

Piezoelectric sensors are a vital component in the modern measurement landscape, bridging the mechanical and electrical domains through an ingenious physical phenomenon. Their ability to convert mechanical stress into electrical signals with high accuracy and responsiveness makes them indispensable in numerous applications. Understanding the underlying piezoelectric effect, material science, and design principles is key to leveraging their full potential and overcoming challenges related to static measurements and environmental sensitivities.

As technology progresses, piezoelectric sensors will become even more integral in smart systems, offering innovative solutions that enhance safety, efficiency, and functionality across industries.

FAQs

Q1: Can piezoelectric sensors measure static forces?

No, piezoelectric sensors are generally not suitable for measuring static forces because the generated charge dissipates over time, making the signal unstable. They excel at detecting dynamic or rapidly changing forces.

Q2: What materials are commonly used in piezoelectric sensors?

Common materials include quartz crystals, lead zirconate titanate (PZT) ceramics, and polyvinylidene fluoride (PVDF) polymers. Each offers different advantages regarding sensitivity, flexibility, and operating temperature ranges.

Q3: How do temperature changes affect piezoelectric sensors?

Temperature variations can cause drift in the sensor output or alter piezoelectric properties. Some sensors include temperature compensation circuits or use materials less sensitive to temperature to mitigate these effects.

Q4: What types of physical quantities can piezoelectric sensors measure?

They can measure force, pressure, acceleration, vibration, strain, and even acoustic signals such as ultrasound.

Q5: Are piezoelectric sensors powered externally?

Piezoelectric sensors generate an electrical signal from mechanical input and do not require an external power source for sensing. However, signal conditioning electronics often require power.

Q6: What are typical applications of piezoelectric sensors in consumer electronics?

They are used in microphones, touch-sensitive buttons, accelerometers for motion detection, and haptic feedback devices.

Q7: Can piezoelectric sensors be miniaturized?

Yes, advances in manufacturing allow for very small piezoelectric elements to be produced, suitable for integration into microelectromechanical systems (MEMS) and portable devices.

Q8: How do piezoelectric sensors differ from strain gauges?

Strain gauges measure static or slowly varying strain by changes in electrical resistance, while piezoelectric sensors measure dynamic changes by generating charge in response to mechanical stress.