In the realm of sensor technology, amperometric sensors have carved out a crucial niche due to their ability to measure the concentration of various chemical species through electrical current. These sensors, widely utilized in fields such as environmental monitoring, medical diagnostics, and industrial process control, rely on electrochemical principles to provide precise, real-time data. Unlike other sensor types that may measure voltage, resistance, or optical changes, amperometric sensors directly quantify analytes by monitoring the flow of electrons generated during redox reactions.

This article explores the fundamental concepts behind amperometric sensors, their operating mechanisms, construction, types, and applications. We also address common challenges and future trends that define this technology’s evolution.

How Does Amperometric Sensors Work

Amperometric sensors operate on the principle of electrochemical oxidation or reduction of analyte molecules at an electrode surface, which generates a measurable current proportional to the analyte concentration. The core concept is straightforward yet powerful: when a target chemical interacts at the sensor’s working electrode, it either donates or accepts electrons, producing an electrical current that can be quantified.

Electrochemical Cell Setup

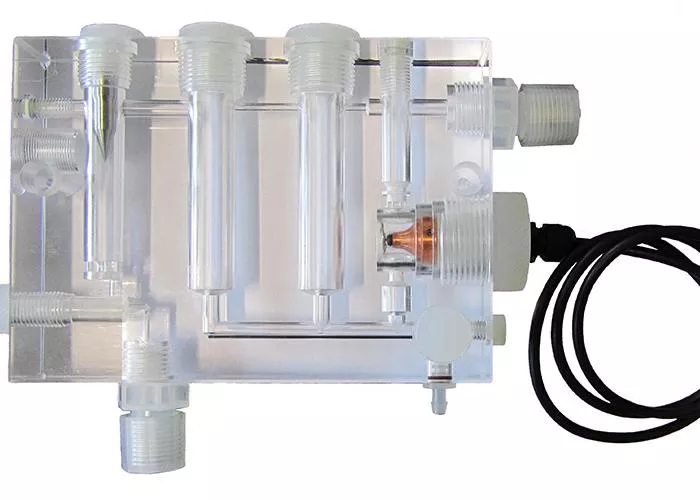

Typically, an amperometric sensor comprises a three-electrode electrochemical cell:

- Working Electrode: The site where the redox reaction of the analyte takes place.

- Reference Electrode: Maintains a stable, known potential against which the working electrode’s potential is measured.

- Counter (Auxiliary) Electrode: Completes the electrical circuit by balancing the current at the working electrode.

The working electrode is polarized at a set potential to drive the desired electrochemical reaction. For example, if detecting oxygen, the electrode may be set at a potential that reduces oxygen molecules to water or hydroxide ions. As the reaction proceeds, electrons are transferred, producing an electrical current that is directly proportional to the analyte’s concentration in the surrounding medium.

Current Measurement and Signal Interpretation

The core measurable in amperometric sensors is current, typically in the microampere to nanoampere range, which arises from the flow of electrons during the redox reaction. By fixing the potential of the working electrode and monitoring the current flow, the sensor produces an output that can be correlated with analyte concentration through calibration.

The current, I, is governed by Faraday’s law of electrolysis:

I = n × F × A × D × (C / δ)

where:

- n = number of electrons transferred per molecule of analyte

- F = Faraday constant (~96485 C/mol)

- A = electrode surface area

- D = diffusion coefficient of the analyte

- C = analyte concentration

- δ = diffusion layer thickness

This relationship underscores how the sensor’s sensitivity depends on physical and chemical factors beyond the analyte itself.

Construction and Materials of Amperometric Sensors

The design of amperometric sensors must optimize several parameters to ensure selectivity, sensitivity, and stability. The choice of electrode materials, membrane design, and supporting electrolytes are fundamental.

Electrode Materials

The working electrode is typically made from noble metals like platinum, gold, or carbon-based materials such as glassy carbon or graphite. These materials offer chemical stability, catalytic activity, and reproducibility in electrochemical reactions. Sometimes, electrodes are modified with catalysts or enzymes to enhance selectivity towards a specific analyte.

Membranes and Diffusion Layers

Many amperometric sensors incorporate selective membranes that allow the analyte to reach the electrode while excluding interferents. For example, oxygen sensors often use a gas-permeable membrane that permits oxygen diffusion but blocks other gases or contaminants. This membrane establishes a controlled diffusion layer, critical for sensor response time and accuracy.

Electrolyte and Reference Electrode

The electrolyte solution provides ionic conductivity within the sensor cell. Reference electrodes, such as silver/silver chloride (Ag/AgCl), maintain a stable potential to ensure reliable measurements. Counter electrodes, often platinum, complete the electrical circuit.

Types of Amperometric Sensors

Based on application and construction, amperometric sensors come in several variants:

Clark-Type Oxygen Sensors

Perhaps the most well-known amperometric sensor, the Clark oxygen sensor, uses a polarizable platinum cathode and a silver anode separated by an electrolyte solution and covered by an oxygen-permeable membrane. Oxygen diffusing through the membrane is reduced at the cathode, generating a current proportional to oxygen concentration. These sensors are widely used in medical blood gas analyzers and environmental monitoring.

Enzyme-Based Amperometric Biosensors

Enzyme electrodes incorporate specific enzymes immobilized on the working electrode to catalyze reactions with target analytes. For example, glucose sensors utilize glucose oxidase to oxidize glucose, producing hydrogen peroxide that is subsequently electrochemically detected. These sensors are prevalent in clinical diagnostics and food quality control.

Gas Sensors

Amperometric gas sensors target gases like carbon monoxide, nitrogen dioxide, or hydrogen sulfide. They typically employ catalytic electrodes with selective membranes and electrolytes tuned for specific gas diffusion and reaction kinetics.

Other Variants

Innovations include microelectrode arrays, solid-state amperometric sensors, and integrated sensor systems combining amperometric detection with other sensing modalities for enhanced performance.

Applications of Amperometric Sensors

The versatility and reliability of amperometric sensors have driven their adoption across diverse sectors:

Environmental Monitoring

Amperometric sensors are instrumental in measuring dissolved oxygen in water bodies, detecting toxic gases in air quality monitoring, and assessing pollutants in soil and industrial effluents. Their sensitivity allows for real-time detection of trace substances, helping enforce environmental regulations and protect ecosystems.

Medical Diagnostics

Blood gas analyzers, glucose meters, and lactate sensors depend heavily on amperometric principles. Their ability to provide rapid and accurate biochemical data at the point of care has revolutionized patient monitoring and treatment.

Industrial Process Control

In manufacturing and chemical processing, amperometric sensors monitor gases and liquid reactants to optimize reactions, ensure safety, and maintain product quality. For example, they regulate oxygen levels in fermentation processes or detect hazardous leaks in petrochemical plants.

Food and Beverage Industry

Amperometric biosensors help monitor fermentation, detect spoilage markers, and ensure the authenticity and safety of products by detecting specific analytes such as glucose, ethanol, or pathogens.

Advantages and Limitations of Amperometric Sensors

Advantages

- High Sensitivity: Capable of detecting low concentrations of analytes.

- Direct Quantification: Current output is directly proportional to analyte concentration.

- Fast Response Time: Rapid electrochemical reactions enable near real-time measurements.

- Wide Application Range: Usable in liquids and gases, for biological and chemical substances.

- Miniaturization: Amenable to microfabrication for portable and implantable devices.

Limitations

- Interference: Other electroactive species can produce false signals unless carefully controlled.

- Electrode Fouling: Surface contamination or biofouling can degrade sensor performance over time.

- Membrane Degradation: Permeable membranes may deteriorate, affecting sensitivity and lifespan.

- Calibration Requirements: Sensors must be periodically calibrated to maintain accuracy.

- Dependency on Environmental Conditions: Temperature, pH, and ionic strength can influence measurements.

Conclusion

Amperometric sensors, by converting chemical information into measurable electrical signals, provide a powerful tool for detecting a broad spectrum of analytes. Their fundamental reliance on electrochemical redox reactions allows for high sensitivity and specificity, making them indispensable in medical diagnostics, environmental monitoring, industrial control, and beyond. Despite challenges such as interference and calibration needs, ongoing material and design innovations continue to enhance their reliability and application scope.

Understanding the working principles, sensor architecture, and operational contexts of amperometric sensors enables engineers and scientists to tailor solutions to complex detection problems. As technology advances, amperometric sensing is poised to play an even more prominent role in delivering precise, real-time chemical insights across multiple domains.

FAQs

What is the main difference between amperometric sensors and potentiometric sensors?

Amperometric sensors measure the current resulting from a redox reaction at a fixed potential, providing direct quantification of analyte concentration. Potentiometric sensors, by contrast, measure the voltage difference between electrodes without current flow, typically related to ion concentration. The fundamental difference lies in current measurement versus voltage measurement.

How do enzyme-based amperometric sensors improve selectivity?

Enzyme-based sensors use specific enzymes that catalyze reactions with a particular analyte, producing electroactive species unique to that analyte. This biochemical specificity improves selectivity by limiting response to target molecules and reducing interference from other substances.

What factors can affect the accuracy of amperometric sensors?

Accuracy can be influenced by electrode fouling, membrane degradation, temperature and pH changes, presence of interfering species, and sensor calibration drift. Careful sensor design and regular maintenance are essential to mitigate these effects.

Can amperometric sensors be used for gas detection?

Yes, many amperometric sensors are specifically designed for gas detection, such as oxygen, carbon monoxide, and nitrogen dioxide sensors. They typically include selective membranes and catalytic electrodes optimized for gas-phase analytes.

How often should amperometric sensors be calibrated?

The calibration frequency depends on the application, sensor design, and operating conditions but typically ranges from daily to monthly. Critical applications may require more frequent calibration to ensure accuracy.

Are amperometric sensors suitable for continuous monitoring?

Yes, many amperometric sensors are designed for continuous monitoring applications, including wearable health devices and industrial process control, provided issues like fouling and membrane stability are managed effectively.