Thermal conductivity sensors play a crucial role in various industrial and scientific applications by measuring the ability of materials, especially gases and liquids, to conduct heat. These sensors are pivotal in fields such as environmental monitoring, gas detection, and process control, where precise measurement of gas composition or thermal properties is essential. The core principle behind these sensors lies in their capability to detect changes in thermal conductivity of the surrounding medium, enabling accurate and rapid analysis.

In this article, we explore the fundamental working principles of thermal conductivity sensors, their design, applications, and advantages. We also touch on how they relate to other sensor technologies such as instrumentation and Hot-Wire Sensors, which share some common measurement concepts.

Principle of Thermal Conductivity Sensors

Thermal conductivity sensors operate by measuring the heat transfer between a heated element and the surrounding environment. The sensor typically consists of a small heated wire or film, whose temperature or resistance changes depending on the heat dissipated through the surrounding gas or liquid. Since different gases and materials conduct heat at varying rates, the sensor can infer the thermal conductivity of the medium based on the heat loss.

The fundamental mechanism is usually based on the relationship between temperature, heat transfer, and resistance. The sensor element is heated electrically, and as heat flows from the element to the medium, the temperature of the element drops. By monitoring this temperature change or the electrical resistance variation of the heated element, the sensor determines the thermal conductivity.

Types of Thermal Conductivity Sensors

There are several variations of thermal conductivity sensors, primarily categorized by their design and measurement technique:

- Hot-Wire Sensors: These sensors use a thin wire heated electrically. The cooling effect caused by the surrounding medium’s thermal conductivity changes the wire temperature, affecting its resistance.

- Hot-Film Sensors: Instead of wire, these use a thin metallic film deposited on a substrate. The film is heated and acts similarly to the wire, measuring changes in thermal conductivity through resistance changes.

- Thermistor-Based Sensors: Utilize thermistors as the heating element and temperature sensor simultaneously, taking advantage of the thermistor’s resistance-temperature characteristic.

Measurement Methodologies

The thermal conductivity sensor’s output is often related to either:

- Constant Temperature Mode: The sensor maintains the heated element at a fixed temperature by adjusting the electrical power. The power needed to maintain this temperature corresponds directly to the thermal conductivity of the medium.

- Constant Power Mode: The sensor applies a constant power to the heating element and measures the resultant temperature change, which varies with thermal conductivity.

Both methods require careful calibration and compensation for environmental variables like pressure and ambient temperature to ensure accurate readings.

Construction and Components of Thermal Conductivity Sensors

The typical construction of a thermal conductivity sensor involves several critical components:

- Heating Element: Usually a fine wire or thin film made of materials such as platinum, tungsten, or nickel. Platinum is often preferred for its stable resistance-temperature characteristic.

- Substrate or Support: A thermally insulating structure that holds the heating element in place while minimizing heat loss through conduction other than to the measured medium.

- Temperature Sensor: Either integrated with the heating element (e.g., in thermistors) or separate, it monitors the temperature of the heated element.

- Electronic Circuitry: Controls the heating power, measures resistance changes, and processes the output signals to convert them into usable data.

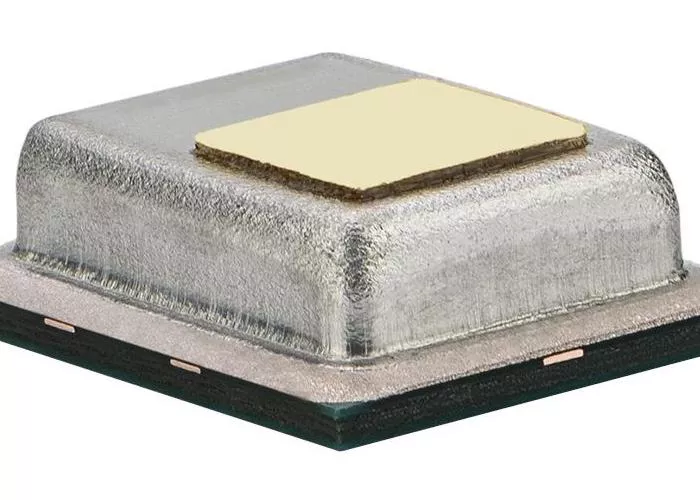

- Protective Housing: Protects the sensor from mechanical damage and environmental contaminants while allowing sufficient contact with the measured medium.

How Thermal Conductivity Sensors Work: Step-by-Step

To better grasp the working of these sensors, here is a stepwise explanation:

- Heating: The sensor’s element is electrically heated, raising its temperature above the ambient temperature.

- Heat Transfer: Heat dissipates from the element to the surrounding medium. The rate of heat transfer depends on the medium’s thermal conductivity.

- Temperature Change: The element’s temperature changes in response to heat loss. In constant temperature mode, the power supplied is adjusted to keep the temperature stable.

- Signal Measurement: The sensor’s electronics measure either the power needed to maintain temperature or the resistance change corresponding to the temperature shift.

- Data Output: The measured parameter is converted into an output signal proportional to the thermal conductivity of the medium.

Applications of Thermal Conductivity Sensors

Thermal conductivity sensors find extensive use across a wide range of industries and applications, such as:

Gas Analysis and Detection

One of the most common uses is gas composition analysis. Since different gases have distinct thermal conductivities, the sensor can detect and quantify specific gases in mixtures. This is critical in industries such as petrochemical processing, environmental monitoring, and industrial safety systems for detecting hazardous gases.

Process Control in Manufacturing

In manufacturing environments, thermal conductivity sensors help monitor gases and fluids to maintain product quality. For example, in semiconductor fabrication or chemical synthesis, precise gas mixture control is vital.

Environmental Monitoring

These sensors assist in monitoring air quality, detecting leaks, or measuring pollutant concentrations. Their fast response time and sensitivity make them ideal for continuous environmental surveillance.

Research and Development

Scientists use thermal conductivity sensors in laboratory settings to characterize materials or analyze gas mixtures under different conditions.

Relation to Other Sensor Technologies

Thermal conductivity sensors often complement other types of sensors, such as Hot-Wire Sensors which also exploit heat transfer principles, or instrumentation sensors in complex systems to provide comprehensive monitoring solutions.

Advantages and Limitations

Advantages

- High Sensitivity: Capable of detecting minute changes in gas composition or thermal properties.

- Fast Response Time: Rapid thermal equilibrium allows quick detection and real-time monitoring.

- Durability: Simple construction with few moving parts enhances robustness.

- Wide Range of Measurands: Useful for different gases, liquids, and even solids in specialized designs.

- Non-Destructive Measurement: Does not alter the sample, preserving its integrity.

Limitations

- Calibration Sensitivity: Requires careful calibration and compensation for ambient conditions like pressure and temperature.

- Cross-Sensitivity: May be affected by humidity, particulate contamination, or mixed gases with similar thermal conductivities.

- Limited Range for Some Gases: Less effective in distinguishing gases with very close thermal conductivity values.

- Material Restrictions: The sensor materials must withstand the operational environment, especially at high temperatures or corrosive atmospheres.

Conclusion

Thermal conductivity sensors are indispensable tools in modern instrumentation and industrial control. Their unique ability to measure thermal conductivity enables precise analysis of gas mixtures, fluid properties, and environmental parameters. Despite some challenges related to calibration and cross-sensitivity, their robustness, sensitivity, and adaptability make them highly valuable across diverse fields.

By understanding their working principles, design, and application scope, engineers and scientists can better leverage these sensors to improve process control, safety, and research accuracy.

FAQs

What types of gases can thermal conductivity sensors detect?

Thermal conductivity sensors can detect a wide range of gases, especially those with thermal conductivities significantly different from the background gas. Common examples include hydrogen, helium, methane, carbon dioxide, and air mixtures.

How do thermal conductivity sensors compare with infrared sensors?

While thermal conductivity sensors measure heat transfer properties, infrared sensors detect gas by absorption of IR radiation at specific wavelengths. Thermal conductivity sensors are often simpler and less expensive but may lack the specificity and selectivity of infrared sensors for certain gases.

Can thermal conductivity sensors be used for liquid measurements?

Yes, but they are primarily designed for gases. Some specialized sensors can measure thermal conductivity in liquids, though the design and calibration become more complex due to the higher density and different heat transfer characteristics of liquids.

What maintenance do thermal conductivity sensors require?

Maintenance involves regular calibration, cleaning to prevent contamination of the heating element, and verification of electrical connections. Sensor longevity depends on the operating environment and protective measures.

Are thermal conductivity sensors affected by pressure changes?

Yes, ambient pressure can influence the heat transfer rate and sensor readings. Most sensors incorporate pressure compensation or require environmental control to maintain accuracy.